MIL-HDBK-1138

Table 13

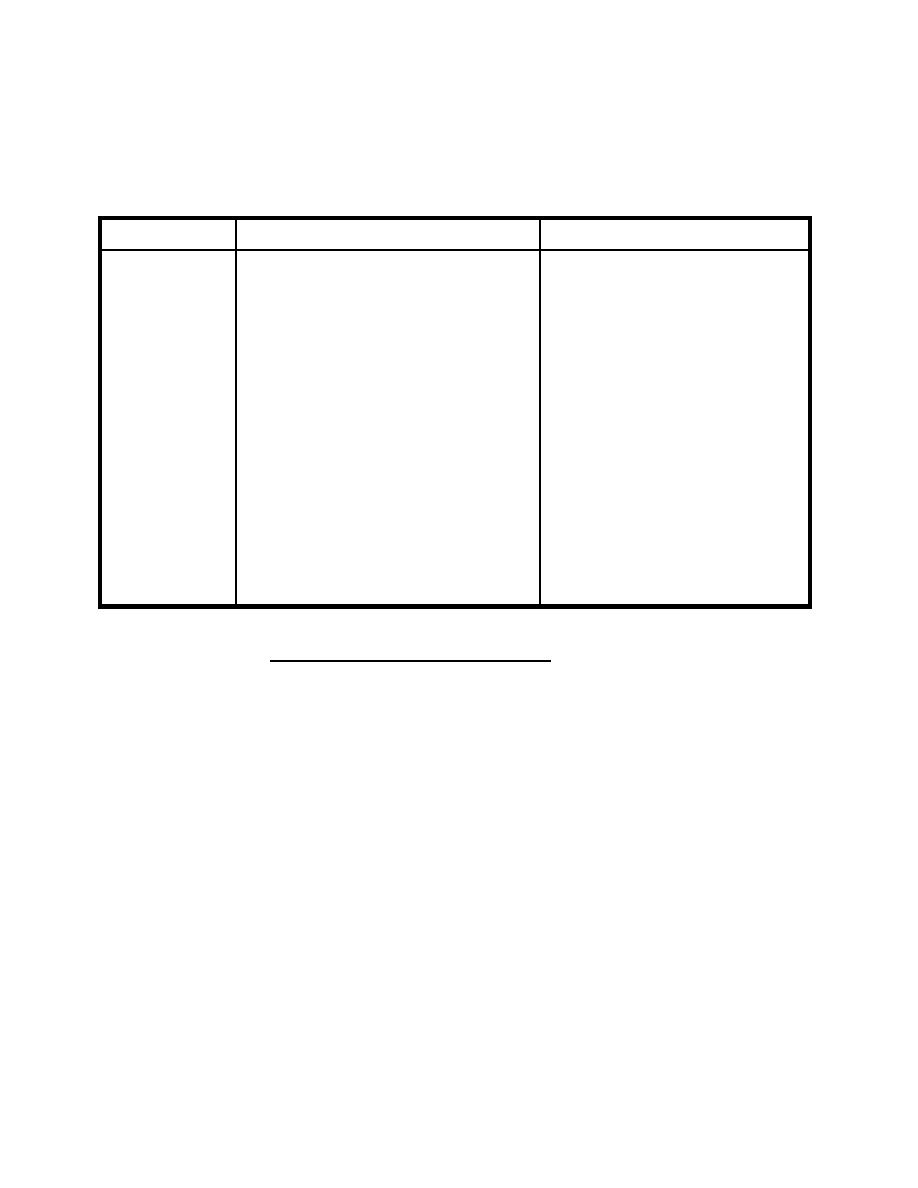

Surface Preparation Standards

Designation

Title

Typical Uses

SSPC SP1

Solvent Cleaning

For all surfaces

SSPC SP2

Hand Tool Cleaning

Where abrasive blasting

not permitted

SSPC SP3

Power Tool Cleaning

Where abrasive blasting

not permitted

SSPC

SP5

White Metal Blast Cleaning

For immersion service

SSPC

SP6

Commercial Blast Cleaning

Noncritical areas

SSPC

SP7

Brush-Off Blast Cleaning

New concrete

SSPC

SP8

Pickling

For hot dip galvanized

SSPC

SP10

Near-White Blast Cleaning

Non-immersion, but

critical service

SSPC SP11

Power Tool to Bare Metal

Special, non-immersion

SSPC SP12

High- and Ultrahigh-

General clean-up;

Pressure Water Jetting

existing concrete

8.2.1.2

Coating Systems for Metals. Maintenance of

coating systems in WWTPs depends upon a number of factors: 1)

knowing the specific coating systems that currently exist within

the plant; 2) implementing an active inspection program; and

3) providing a good maintenance painting program. Maintenance

painting operations are different than new construction painting

operations. With a proper maintenance painting program, total

recoating is generally unusual rather than normal.

Inspection of all coating surfaces should be performed

routinely. Be observant for the first signs of coating

breakdown, such as rust staining and streaking, blistering of

coating, peeling of coating, and other signs of deterioration.

Coatings on steel substrates will generally show the first signs

of failure at sharp edges, such as edges of structural steel,

adjacent to welds, and around threads of bolts and edges of nuts.

Failures on flat surfaces take much longer to develop. In

immersion service, coating failures also develop first at edges

but can also develop on flat surfaces because of imperfections

and defects. Linings in tanks and vessels are especially

critical.

80

Previous Page

Previous Page