MIL-HDBK-1003/11

4.3.4 Exhaust Gas Heat Recovery. Exhaust gases discharged from diesel

generators range in temperature up to approximately 600deg. F (316deg. C) at

full load. The temperature depends on the size of the unit, the fuel used,

and the combustion cycle (i.e., 2 or 4 stroke engines). Larger engines

operate at lower temperatures. Exhaust gas recovery systems include the

following:

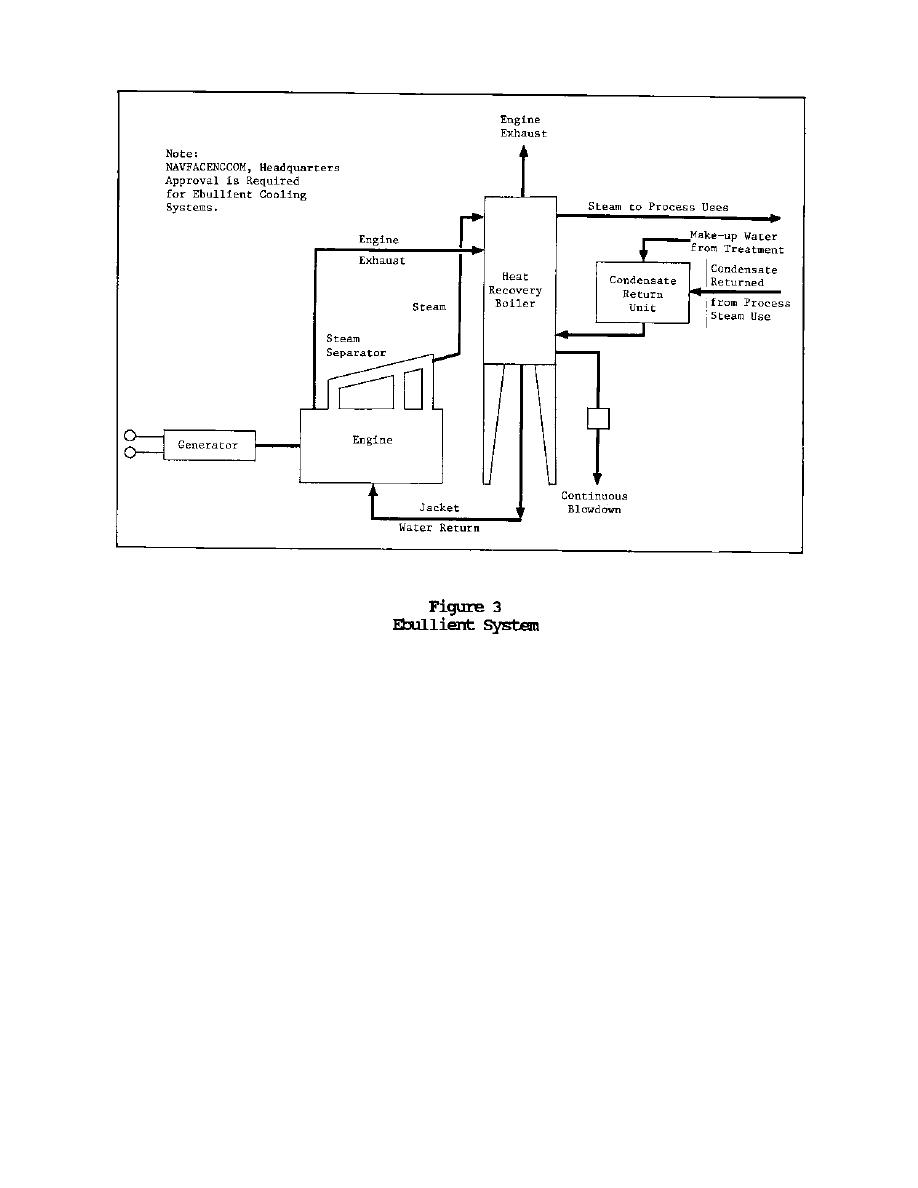

a) Heat is recovered in the form of hot water or steam in a heat

recovery boiler which also acts as an exhaust silencer. These devices are

often referred to as "Heat-Recovery Silencers." Heat recovery boilers

receiving exhaust gas shall be designed to run dry when there is no thermal

load. Diverter valves shall not be used.

b) Hot water cogeneration is often preferred over steam systems.

Advantages include ease of process control, independent of operating

temperatures which are critical for low pressure/temperature steam

cogeneration.

c) Some process configurations use heat recovered from jacket and

lubricant cooling systems to preheat heat-recovery boiler feedwater and fuel

oil.

d) Combined cycle applications are often used to generate additional

power and to produce hot water or to lower steam pressure for usage.

19

Previous Page

Previous Page