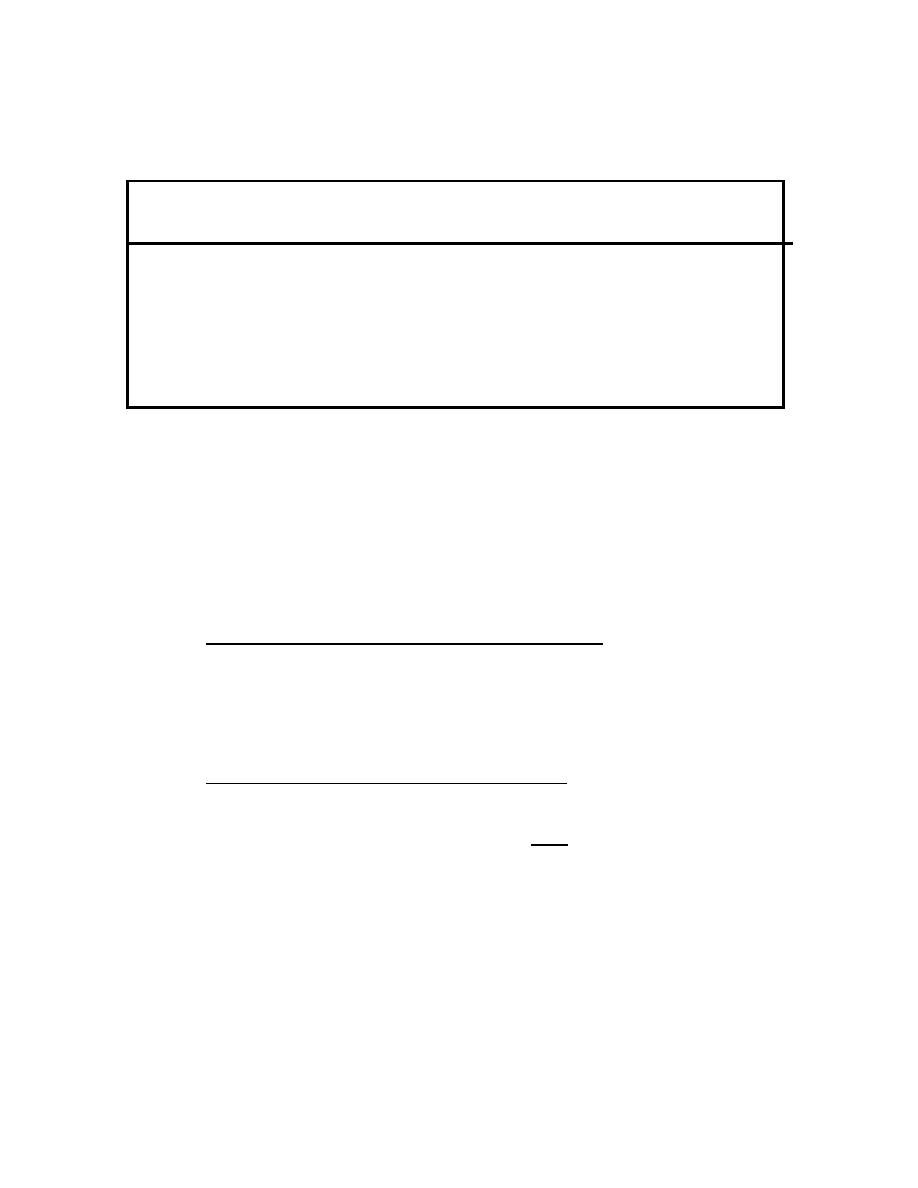

MIL-HDBK-1004/10

Table 7

Results of Structure-to-Electrolyte

Potential Measurements

POTENTIAL VERSUS

POTENTIAL VERSUS

TEST POINT

COPPER/COPPER

TEST POINT

COPPER/COPPER

SULFATE (V)

SULFATE (V)

P1

-0.883

F1

-0.832

P2

-0.876

F2

-0.810

P3

-0.864

F3

-0.765

P4

-0.927

F4

-0.746

P5

-1.058

F5

-0.421

P6

-1.012

F6

-0.386

P7

-0.881

F7

-0.405

P8

-0.854

F8

-0.413

P9

-0.836

F9

-0.419

Another field measurement associated with interference is the

measurement of the current flowing through a structure. As shown in Figure

23, the procedure involves the measurement of the potential drop along a

section of the structure which is carrying the current. The section of

structure is initially calibrated by passing a known current through the

section using the outer set of test leads. Subsequent measurements of the

potential drop are then referred to the calibration factor for the structure

and the current is calculated. This measurement is called an IR drop test.

Test stations are commonly installed on long pipelines to measure the current

flowing in them in order to detect changes in the current which could be an

indication of either interference or problems with the cathodic protection

system on the pipeline.

Control of Interference - Anode Bed Location. The single most

5.2.1.2

important factor in controlling interference is the location of the anode bed.

In general, the remote anode beds commonly used in impressed current cathodic

protection systems cause more problems with interference than do sacrificial

anode systems where the anode-to-structure distances are usually in the order

of 10 feet or less and the driving potential is small (1 V or less). The

influence on foreign structures should be a primary consideration in the

location of remote anode beds.

Control of Interference - Direct Bonding. One method of correcting

5.2.1.3

interference is to bond the foreign structure to the protected structure. The

bonding can either be a direct low-resistance connection or a resistive bond.

Figure 24 shows correction of an interference problem by direct bonding.

Bonding both pipes together, essentially makes both pipes the protected line.

A test station is usually installed at such a location in order to either

verify the continuity of the bond, or to measure the current flowing through

the bond. To allow for future bonding and testing, a bond station should be

installed wherever pipelines cross and at other locations where interference

is possible.

43

Previous Page

Previous Page