MIL-HDBK-1004/10

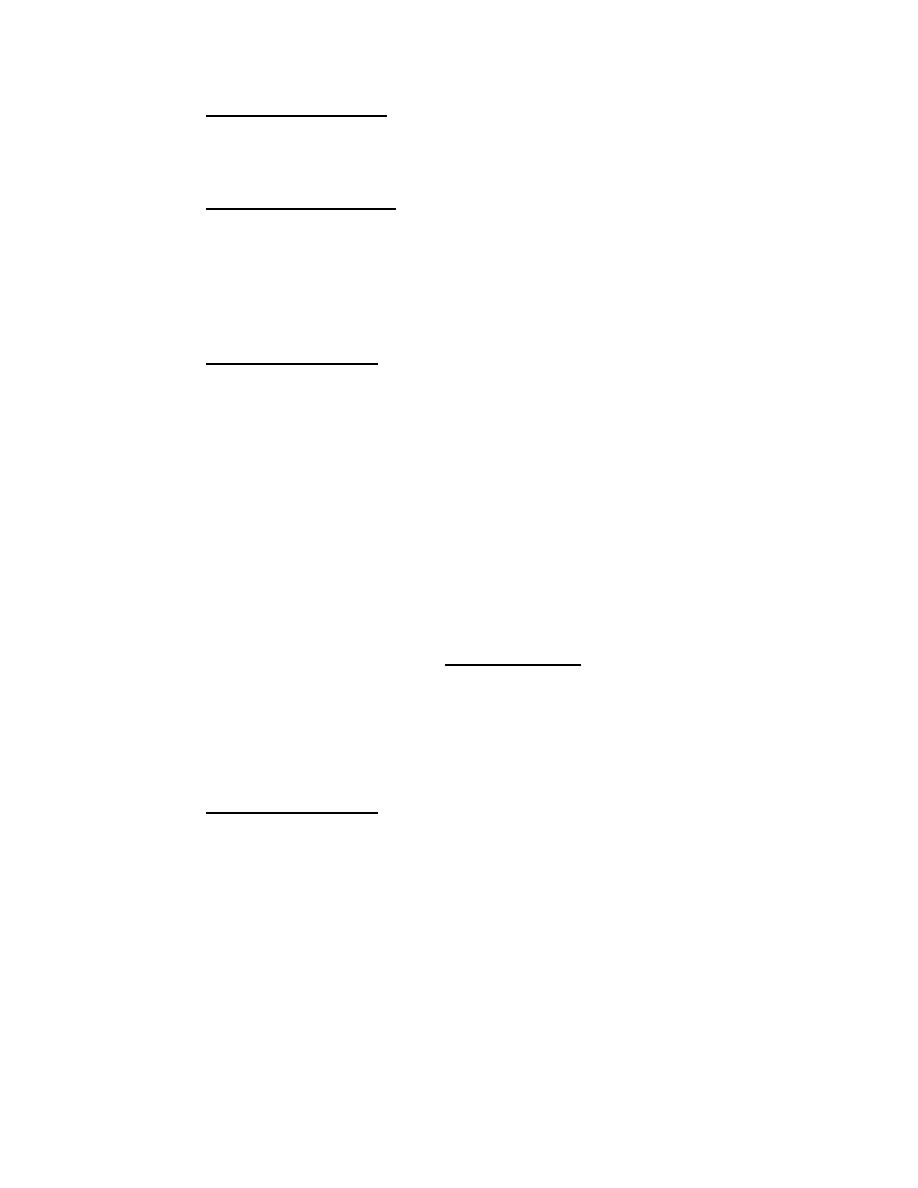

Rectifier Components. Figure 32 is a circuit diagram for a typical

6.5.1

single-phase full-wave bridge type rectifier showing the components found in

most standard rectifiers of this type. The diagram also shows an external

switch and circuit protection device which is mandatory for all DOD rectifier

installations.

Transformer Component. The transformer reduces the incoming

6.5.1.1

alternating current voltage to the alternating current voltage required for

the operation of the rectifing component. In most impressed current cathodic

protection rectifiers, the voltage output from the secondary windings can be

varied by changing the effective number of secondary windings through a system

of connecting bars or "taps." Two sets of taps are normally present, one for

coarse adjustments and one for fine adjustments. By manipulation of these

taps, the voltage should be adjustable to vary the rectifier voltage from

zero, through at least 20 equal steps, to its maximum capacity.

Rectifying Elements. The alternating current from the secondary

6.5.1.2

windings of the transformer element is converted to direct current by the

rectifying elements or "stacks." The stack is an assembly of plates or diodes

and may be in several configurations. The most common rectifying elements are

selenium plate stacks and silicon diodes. Each has advantages and

disadvantages as discussed in para. 6.5.3.8. The most common configurations

of rectifying elements are the single-phase bridge, single-phase center tap,

three-phase bridge, and three-phase wye. These arrangements are described in

detail in para. 6.5.2. The rectifying elements allow current to flow in one

direction only and produce a pulsating direct current. The rectifying

elements do allow a small amount of alternating current to pass. This

"ripple" is undesirable and should be held to low levels. Rectifiers are not

100 percent efficient in converting alternating current to direct current.

This is due to the presence of alternating current and to inherent losses in

the rectifying elements which result in heating of the stacks. Silicon

elements are more efficient than selenium elements at high output voltages but

are more susceptible to failure due to voltage overloads or surges. The

efficiency of a rectifying element is calculated by the following equation:

dc output power

EQUATION:

Efficiency (%)

=

ac input power x

100

(16)

Typical efficiencies of single-phase rectifying elements are in the order of

60 to 75 percent but can be increased by filtering the output or by using a

three-phase circuit. Selection of appropriate circuit type is discussed in

para. 6.5.2. Selection of silicon versus selenium rectifying elements is

discussed in detail in para. 6.5.3.8.

Overload Protection. Overload protection in the form of either

6.5.1.3

circuit breakers, fuses, or both should be used on all impressed current

rectifiers. In addition to protecting the circuits from overloads, circuit

breakers provide a convenient power switch for the unit. Circuit breakers are

most commonly used on the alternating current input to the rectifiers and

fuses are most commonly used on the direct current outputs. In addition to

circuit breakers and fuses, the rectifier should be furnished with lightning

arresters on both the ac input and dc output in order to prevent damage from

lightning strikes or other short duration power surges. The respective firing

voltages of the lightning arresters should be higher than the ac input and dc

61

Previous Page

Previous Page