MIL-HDBK-1004/10

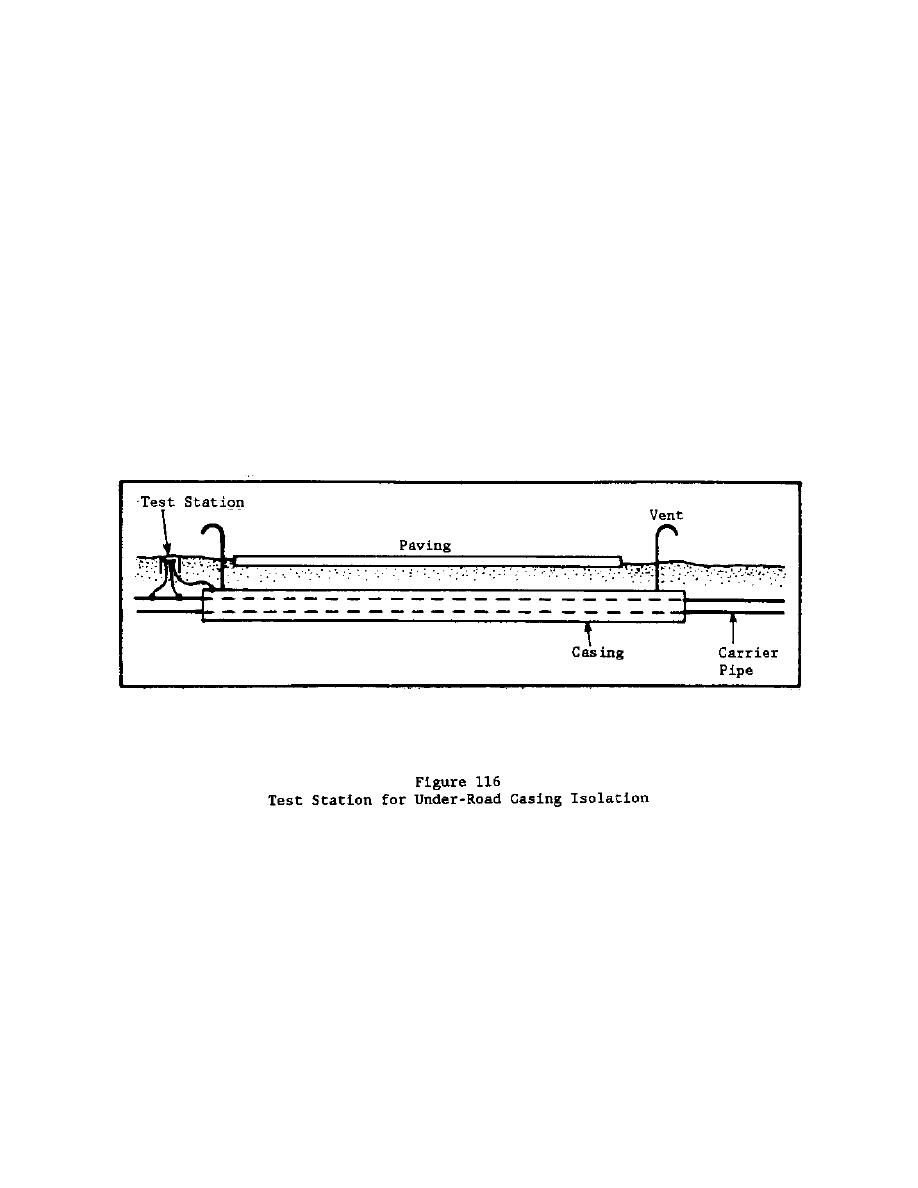

test station should be installed at the casing for future measurements.

Figure 116 shows a test station for casing isolation testing.

10.5.2 Foreign Pipeline Crossings. Newly installed pipelines are common

installed under existing lines. The owner of the foreign line should be

contacted to obtain permission to install test leads and possibly to coat

short section of the foreign line. Since solutions to problems at foreig

crossings require cooperative efforts, effective coordination is essentia

As discussed in Section 13 of this handbook, corrosion coordinating

committees have been established in many areas to facilitate coordination

such efforts. Clearance of 2 feet between all lines at crossings is

recommended. If 1-foot clearance cannot be obtained, the use of an

insulating mat as shown in Figure 63 is required. Direct contact between

lines should be avoided at almost any cost. Installation of insulating m

the area or if a new coated line is crossing a poorly coated or uncoated

line. Installation of test stations with provisions for bonding at all

crossings is essential.

10.5.3 Insulating Joints. Insulating, or isolating joints must be selec

so that the materials are compatible with the service environment.

Isolation of steam conduits is especially troublesome. Isolating couplin

must be properly assembled and tested to insure that they will be effecti

When used on welded pipelines, short "spools" of pipe should be welded to

each flange. The flange should then be assembled and the section welded

into the pipeline. This will prevent mechanical damage to the insulating

joint associated with misalignment. Flanges should be tested with a radi

frequency type insulation checker after assembly to insure that they have

been properly assembled. Effectiveness of buried flanges must be verifie

by impressing a

215

Previous Page

Previous Page