UFC 4-023-03

25 January 2005

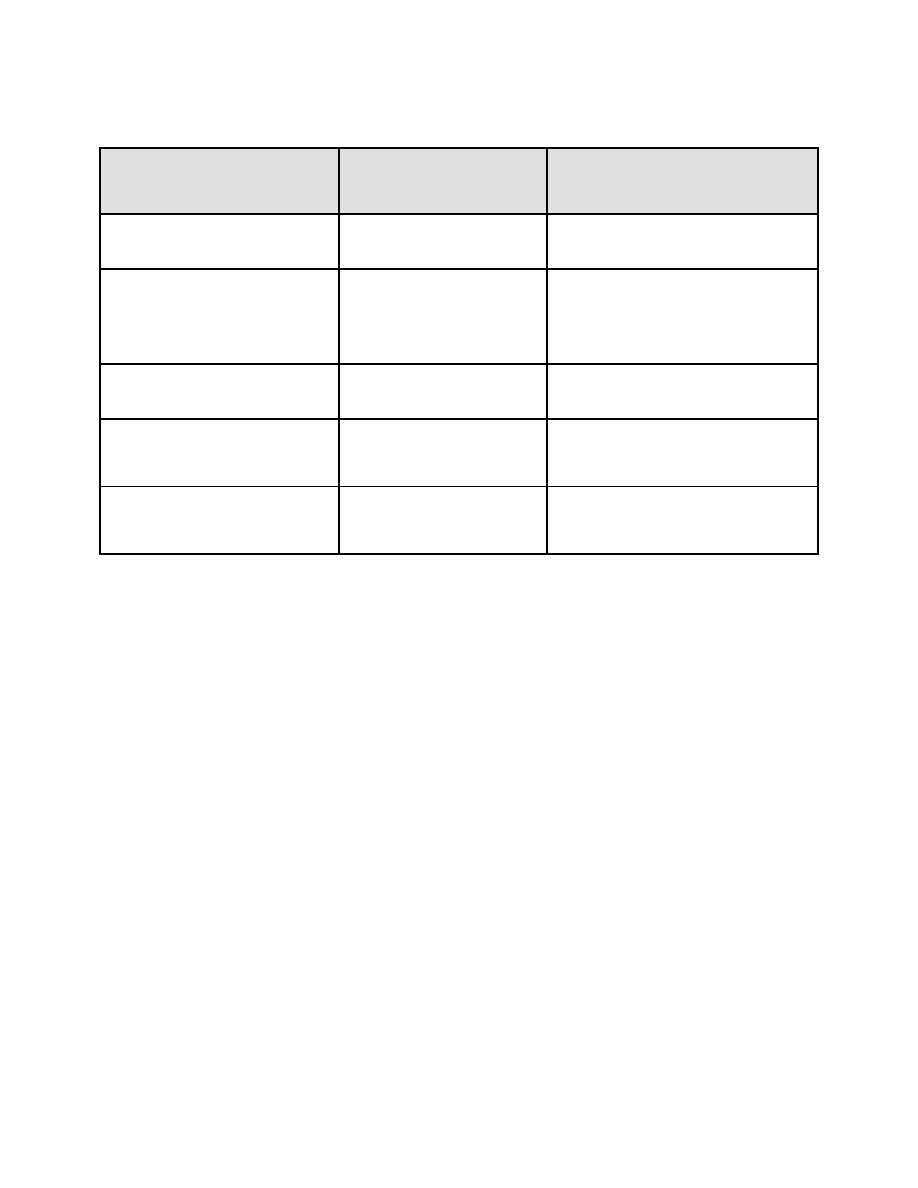

Table 8-2 Acceptability Criteria and Subsequent Action for Cold-Formed Steel

Subsequent Action for AP

Structural Behavior

Acceptability Criteria

Model

Φ MnA

Element Flexure

Section 8-3.1.1

AISI/COS/NASPEC

Element Combined Axial

2001 Chapter C5

Section 8-3.1.2

and Bending

Interaction Equations

Φ VnA

Element Shear

Section 8-3.1.3

Connection Design

Connections

Section 8-3.1.4

StrengthA

Deformation Limits,

Deformation

Section 8-3.2

defined in Table 8-3

A

Nominal strengths are calculated with the appropriate material properties and over-

strength factor Ω; all Φ factors are defined per AISI/COS/NASPEC 2001.

8-3.1.1

Flexural Resistance of Cold-Formed Steel.

For cold-formed steel, the flexural design strength is equal to the nominal

flexural strength, multiplied by the strength reduction factor Φ; calculate the nominal

flexural strength per AISI/COS/NASPEC 2001 procedures.

For Linear Static Analysis, if the required moment exceeds the flexural design

strength and if the geometry and supports of the cold-formed steel member are

sufficient for a plastic hinge to form and undergo significant rotation, add an equivalent

plastic hinge to the model, by inserting a discrete hinge at the correct location within the

member. For a connection with a plastic hinge, insert the hinge at the offset from the

member end; use engineering analysis and judgment to determine the offset length.

Also, apply two constant moments, one at each side of the new hinge, in the

appropriate direction for the acting moment; see Figure 3-9. For Nonlinear Static and

Dynamic Analysis, use software capable of representing post-peak flexural behavior.

Ensure that shear failure will not occur prior to developing the full flexural design

strength.

If the structural element is not able to develop a constant moment while

undergoing continued deformations, remove the element when the internal moment

exceeds the flexural design strength. Redistribute the loads associated with the

element per Section 3-2.4.3.

8-6

Previous Page

Previous Page