UFC 4-023-03

25 January 2005

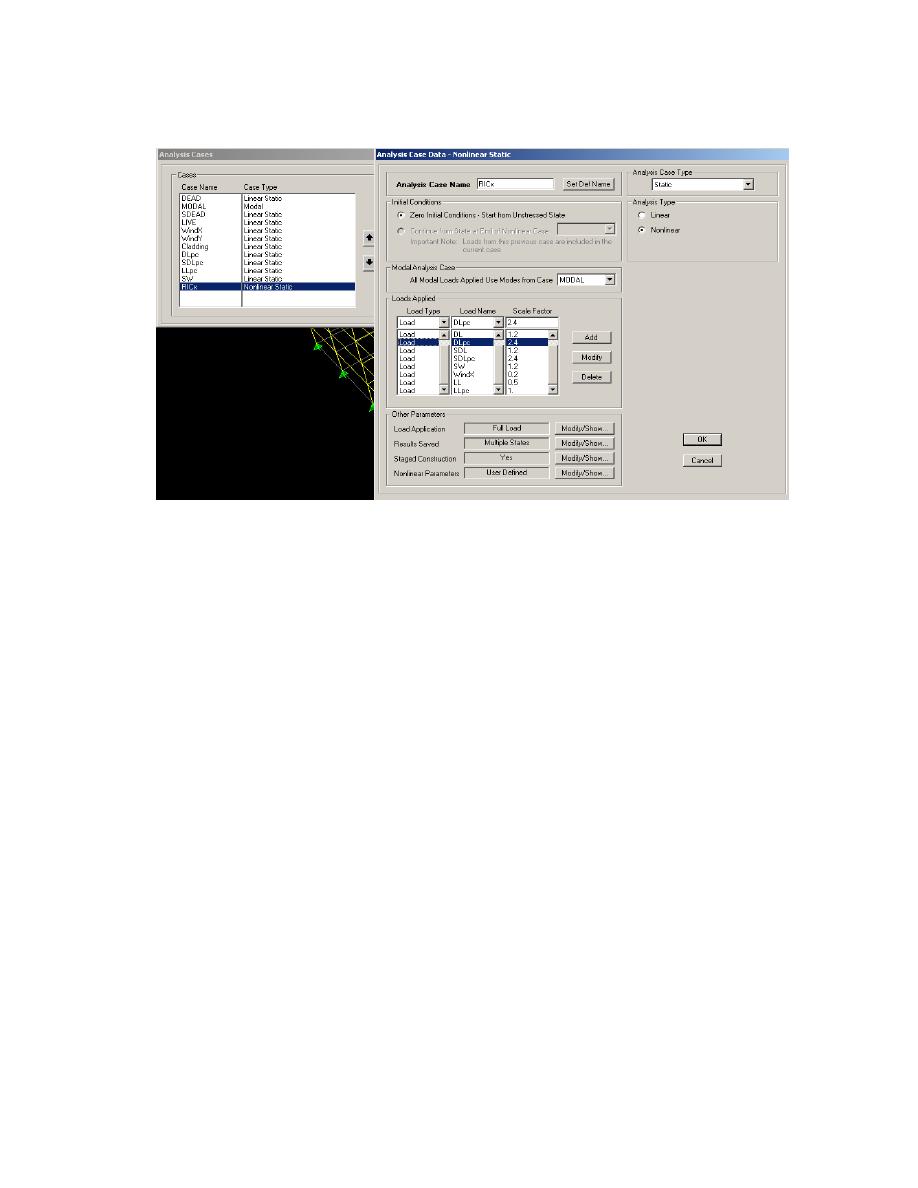

Figure D-9 Progressive Collapse Load Combination Input

D-5.5

Run Analysis.

It is important to check that both stages of every analysis case converge. If

the analysis does not converge, there is a problem with the model and it must be fixed.

The problem could be a numerical problem with assumptions made in SAP, but the

most likely reason is that the model has a plastic hinge that failed or a mechanism has

formed. At this point, the model cannot support the load and causes a progressive

collapse. See Section D-6 (redesigning members). If the model converges, proceed to

Section D5-6.

D-5.6

Progression of Hinge Formations.

1)

Since the analysis did not converge, members were redesigned. To

determine which members must be redesigned, step through the incomplete

progression of plastic hinge formations. The final step saved by SAP will often

give the best results on which columns to redesign, but not always. See Figures

D-10 through D-12 for the final step in the hinge formations of an analysis that did

not converge.

2)

To view the plastic hinges, click Display Deformed Shape. Choose an

analysis case and click to the last step of that case. Any hinge that forms will

"light up," and its color denotes the region the hinge has progressed (see Figure

D-6). Any hinge that is orange (D) or red (E) has failed.

3)

Once members have been selected to be redesigned, rerun the analysis.

Repeat this process until the structure converges. The engineer must check each

analysis case to make sure that no hinge has failed. Once the analysis converges

and no hinges fail, proceed to Section 5-7 (shear check). See Table D-4 for final

member sizes and Figure D-13 for final deformed shape and hinge formations.

D-12

Previous Page

Previous Page