UFC 4-211-01N

25 October 2004

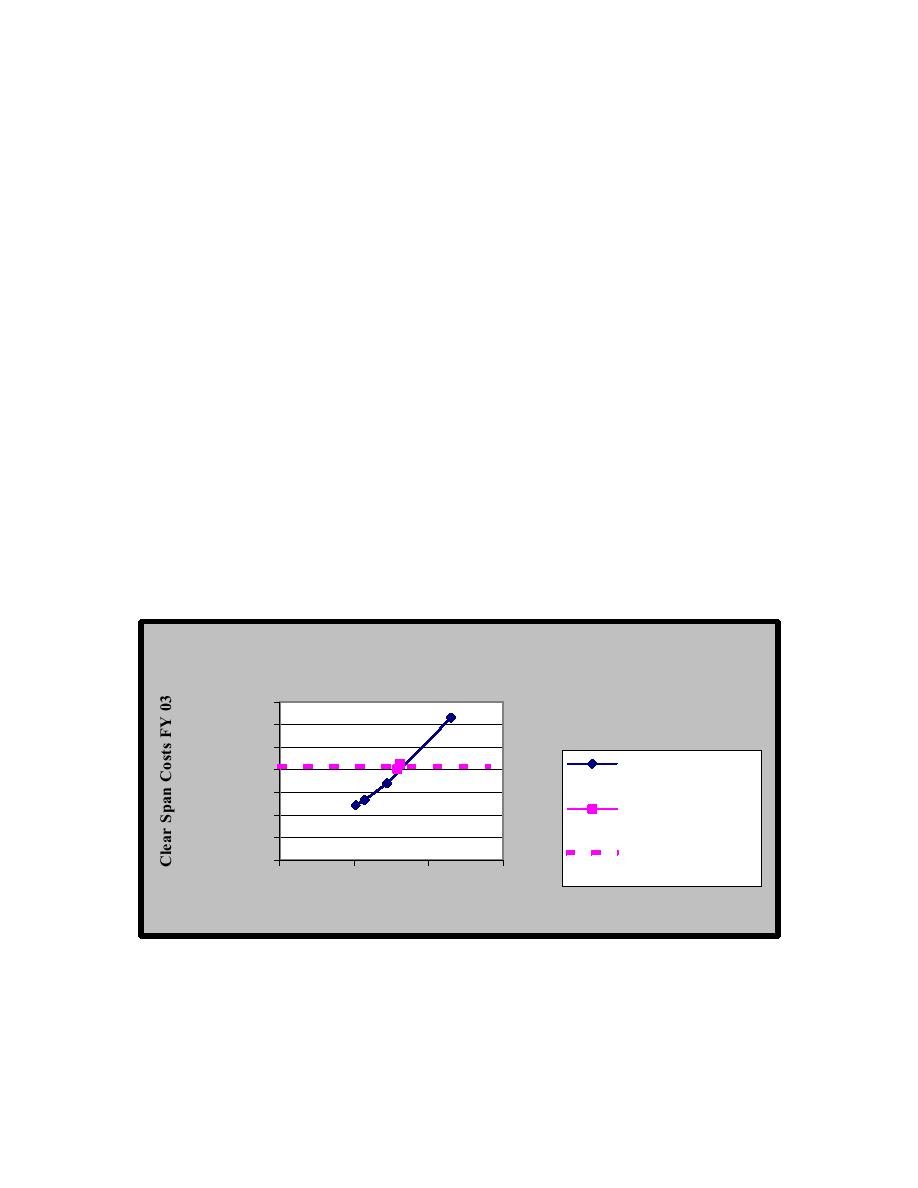

The designer is cautioned that the figure is a simplification of the

existing background information. The information presented is based upon the

assumption that a standard Type I Maintenance Hangar is being produced. It

has been further assumed that the hangar bay space is approximately 30 m

(85 feet) deep and that the design conditions are as found in Norfolk, VA. Figure

4-1 presents estimated cost based on the pounds per square foot of structural

steel required to construct a facility of approximately 7200 m2 (77000 ft2) total

area. The figures represent an average cost, including both the hangar (OH)

area and the office and shop (O1/O2) areas. It is assumed that the ratio between

OH and O1/O2 areas remains relatively constant in all Type I facilities.

The graphical representation provided by Figure 4.1 shows an

economical comparison of alternative structural framing systems for planning

purposes. The project planning/design team should carefully evaluate the roof

structural framing systems and optimize the design selected considering the

long-term interest of the airfield mission.

NOTE: When generating cost estimates of low bay-type I / high bay-type II single

module versus multiple module and the differences associated with the primary

roof framing system, please contact the NAVFAC Engineering Innovation and

Criteria Office for additional guidance when preparing MCON 1391

documentation.

Figure 4-1 Hangar Clear Span Roof Costs

Hangar Clear-Span Roof Costs

,000,000

,000,000

,000,000

Header-Truss

,000,000

Systems

,000,000

Cantilever Systems

,000,000

,000,000

Cantilever Average

||content||

0

50

100

150

Single Clear Spans, Meters

4-5.8

Roof Systems. Roof systems are typically metal deck on a

combination of open web steel joist and structural steel substructure.

Historically, it has been difficult to maintain the necessary level of quality control

required to weld decks at sidelaps and at supports. The designer is cautioned to

47

Previous Page

Previous Page