UFC 3-250-03

15 May 2001

(4) Asphalt contents for specimens. The quantity of asphalt required for a particular aggregate

is very important to assure satisfactory performance. The procedures to follow are described in (5)

(Selection of design compaction method) below. An estimate for the optimum amount of asphalt based

on total weight of mix is normally made in order to start the laboratory tests. Laboratory tests usually are

conducted for a minimum of five asphalt contents: two above, two below, and one at the estimated

optimum content. Incremental changes of 1 percent of asphalt may be used for preliminary work, but

increments of 0.5 percent are generally used when the optimum asphalt content can be estimated and

for final design.

(5) Selection of design compaction method. The Department of the Army and Air Force allow

two methods of compacting asphalt paving mixtures in the laboratory--the Marshall and the Gyratory

Testing Machine methods. The procedures for conducting the Marshall mix design tests are described

in CRD-C 649. The procedure for gyratory compaction is given in CRD-C 651 or the standard testing

method of ASTM D 3387 except as follows:

(a) Use 101.6 millimeter (4-inch) diameter molds in lieu of 152.4 millimeter (6-inch) molds

when Marshall stabilities and flows are to be determined.

(b) Use mixing and compaction temperature requirement as given in CRD-C 649.

(c) The Gyratory Testing Machine setting and equivalent compaction requirements shall

be as listed in table 2-5.

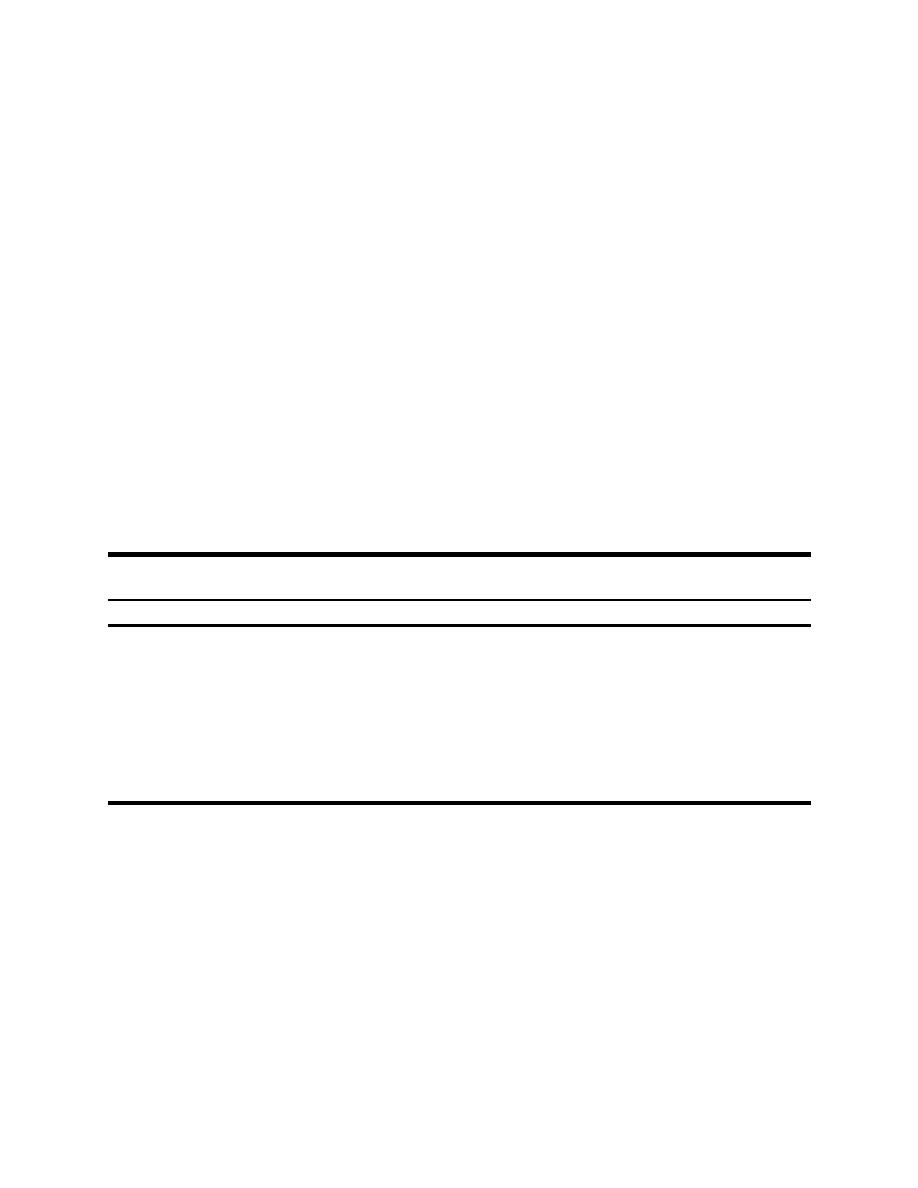

Table 2-5

Traffic Type and Gyratory Compaction Requirements

Type of Traffic

Gyratory Compaction Requirement

Tire pressures less than

Gyratory compaction at 690 kPa

690 kPa (100 psi)

(100 psi), 1-degree, 30 revolutions (50 blows Marshall

equivalent)

Tire pressures 690 kPa

Gyratory compaction at 1,380 kPa

(100 psi) and greater but less

(200 psi,) 1-degree, 30 revolutions (75 blows Marshall

than 1,586 kPa (230 psi)

equivalent)

Tire pressures 1,586 kPa

Gyratory compaction at 1,655 kPa

(230 psi) and greater

(240 psi), 1-degree, 60 revolutions (preferred but not

mandatory for Army and Air Force airfields)

In the event an airfield pavement is to be subjected to aircraft with tire pressures of 1,586 kPa (230 psi)

or more, the Gyratory Testing Machine (GTM) method is mandatory for Army airfield pavements and is

preferred but is not mandatory for Air Force airfield pavements. If the GTM method is used for design, it

should also be used for control testing. If the GTM cannot be used for control testing, the Marshall

apparatus can be used by developing a correlation between the GTM and Marshall specimens for the

job mix. Care should be taken to insure that excess breakage of the aggregate particles does not occur

during Marshall compaction.

(6) Tabulation of data. After the laboratory design method has been selected and test

specimens have been prepared, data should be tabulated on forms similar to those shown in CRD-C

649 and CRD-C 650 if the Marshall procedure is used. These forms, along with the forms shown in

CRD-C 651, are normally used for the gyratory procedure. Arranging data as shown in table 2-6 will

facilitate tabulation of specimen test property data and is preferable to similar but less complete methods

2-18

Previous Page

Previous Page