UFC 3-250-03

15 May 2001

(6) Uncured FRS can be adversely affected by changes in weather conditions such as rain or

freezing temperatures.

(7) Only structurally sound pavements are suited for a FRS.

(8) Proper mixture design and application are very important for obtaining a satisfactory job.

d. Material requirements.

(1) Coal-tar emulsion. The binder material used in a fuel-resistant sealer is a coal tar

emulsion. The coal tar emulsion is usually specified as having to meet the requirements of Federal

Specification R-P-00355E or ASTM D 5727.

(2) Aggregates. Aggregates shall be either natural or manufactured angular aggregate. The

aggregate shall be clean and free of organic and other objectionable material. The aggregate shall meet

the gradation requirements as given in table 4-5.

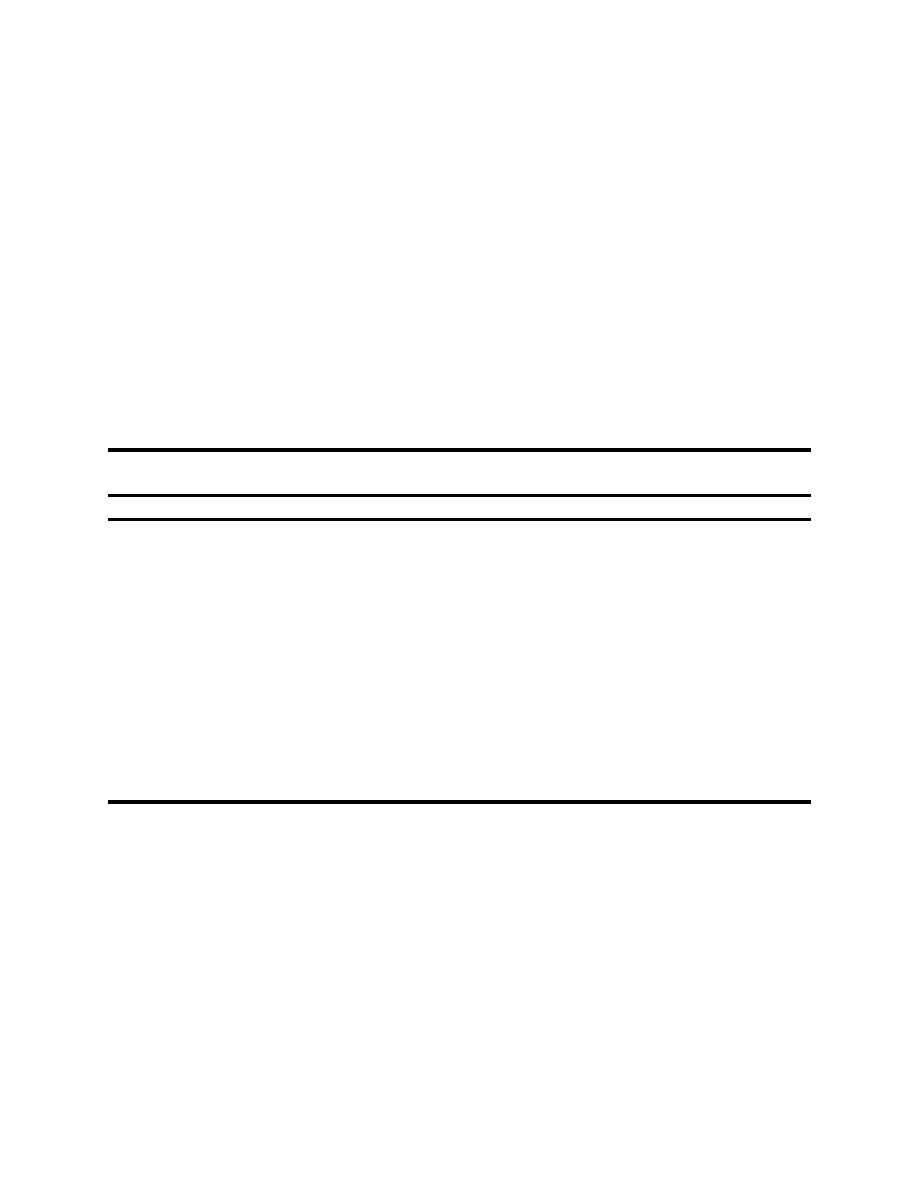

Table 4-5

Fuel Resistant Sealer Minimum Application Rates and Corresponding Aggregate Gradations

Gradation Type

Coarse

Medium

Fine

Minimum Application Rate, L/m2 (gal/yd2)

1.35 (0.3)

1.0 (0.22)

0.72 (0.16)

Sieve Size

2.36 mm (No. 8)

100

100

100

1.18 mm (No. 16)

98-100

100

100

(No. 20)

85-100

98-100

100

600 Fm (No. 30)

25-90

85-100

98-100

(No. 40)

5-30

30-90

85-100

300 Fm (No. 50)

210

8-35

35-90

(No. 70)

0-4

3-11

10-40

150 Fm (No. 100)

0-2

0-4

4-12

(No. 140)

--

0-2

0-4

75 Fm

(No. 200)

--

--

0-2

(3) Water. Only potable water shall be used in a FRS mixture. The amount of water required

shall be determined from laboratory testing prior to construction. A small amount of additional water

may be required under very high temperature pavement conditions.

(4) Additives. Additives sometimes used in FRS's include various types of polymer and silicon

materials. These materials may be added to the FRS mixture in the field or added to the coal-tar

emulsion during the emulsifying process. The polymer materials most often used are latex combinations

of acrylonitrile and butadiene.

e. Design.

(1) General. The design of FRS mixtures has historically been based on the selection of

materials (sand, water, and additives) from an allowable range based on a per gallon of coal-tar

4-9

Previous Page

Previous Page