UFC 3-570-06

JANUARY 31 2003

2-6.1.3

Aluminum Anodes. Aluminum galvanic anodes are a more recent

development than either zinc or magnesium alloys. Their primary use is in the

protection of structures in seawater. However, they have occasionally been used in

fresh water or in soil. When the original anodes used are aluminum alloy and their

performance has been satisfactory, they should be replaced with anodes of the same

type.

Early formulations of aluminum alloys for use as a sacrificial anode contained

mercury. While the amount of mercury contained in the alloy is small, the mercury

tends to concentrate in the anode stubs that remain after the bulk of the anode has

been consumed. Precautions should be taken during removal of the stubs, especially

by methods that generate heat, to prevent mercury poisoning. Mercury containing

aluminum alloy anode stubs should be disposed of properly.

The electrical potential of type I and type II aluminum anodes is

approximately -1.10 volts DC to copper/copper sulfate in soil, and for type III, -1.15 volts

DC. The consumption rate for aluminum anodes is Type I, 21 kilograms (6.8 pounds)

per amp year, Type II, 5.2 kilograms (11.4 pounds) per amp year, and Type III, 3.4

kilograms (7.6 pounds) per amp year. It is important that replacement anodes be of the

same type as the originals, as the design of the system is dependent on the anode

material used. However, the Type III anodes are now used almost exclusively to avoid

the detrimental and safety hazards of mercury..

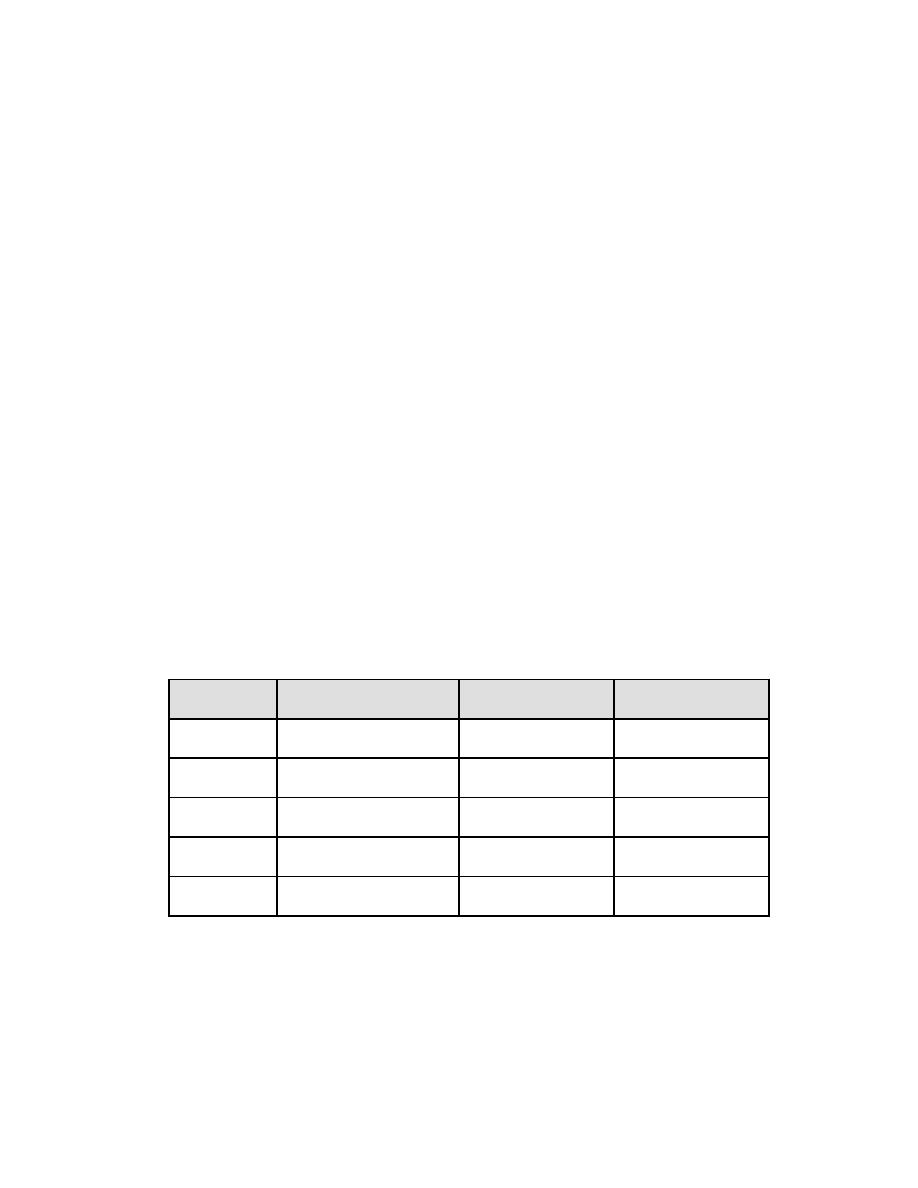

Table 2-7. Compositions of Aluminum Anodes

ELEMENT

TYPE I

TYPE II

TYPE III

Zinc

0.35% - 0.50%

3.5% - 5.0%

3.0%

Silicon

0.10% max

-

0.1%

Mercury

0.035% - 0.048%

0.035% - 0.048%

-

Indium

-

-

0.015% max

Aluminum

Remainder

Remainder

Remainder

2-33

Previous Page

Previous Page