MIL-HDBK-1110

Table 7

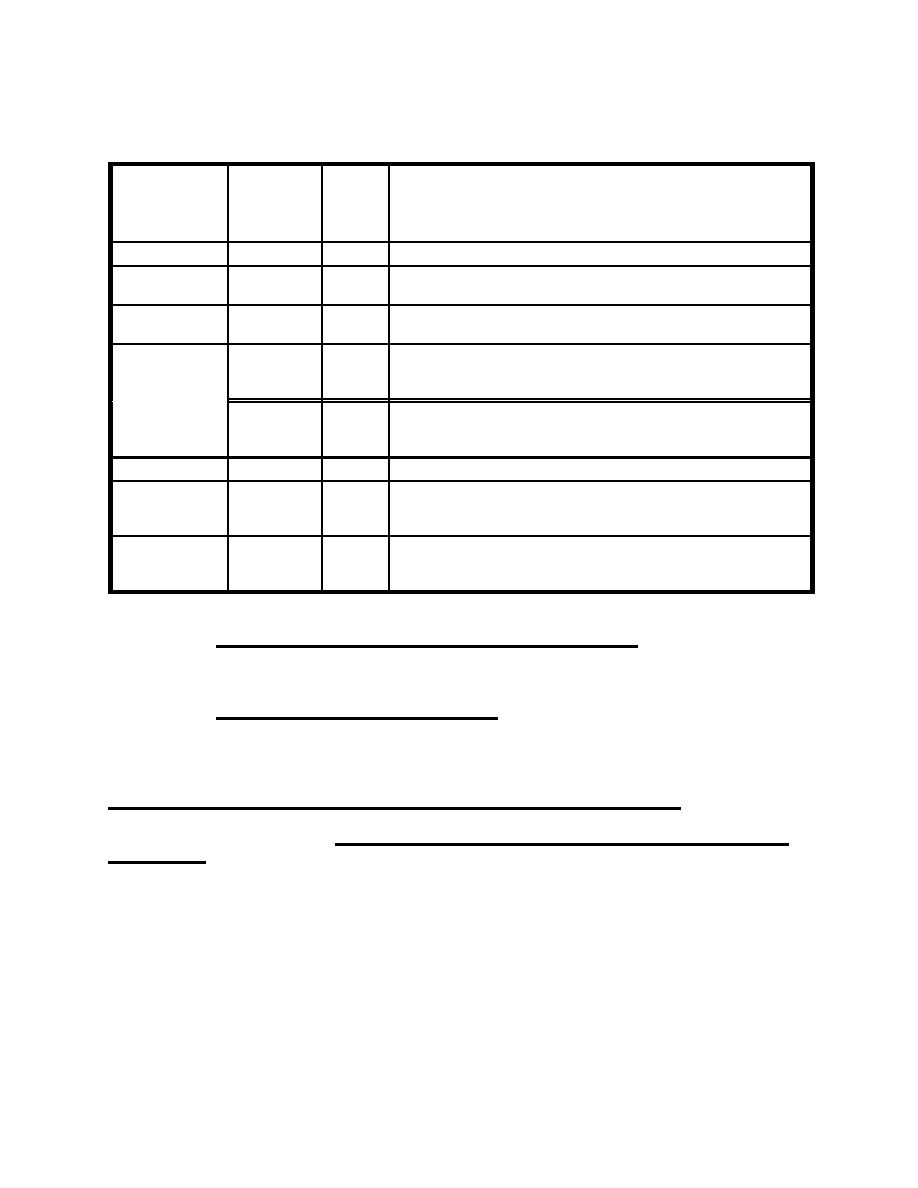

SSPC and NACE Standards for Cleaned Steel Surfaces

Method

SSPC No.

NACE

Intended Use

No.

Solvent

SSPC SP 1

Removal of oil and grease prior to further

Cleaning

cleaning by another method

Hand Tool

SSPC SP 2

Removal of loose mill scale, rust, and paint

Power Tool

SSPC SP 3

Faster removal of loose mill scale, rust, and

coatings than hand tool cleaning

White Metal

SSPC SP 5 NACE 1 Removal of visible contaminants on steel

Blast

surfaces; highest level of cleaning for steel

Commercial

SSPC SP 6 NACE 3 Removal of all visible contaminants except

Blast

that one third of a steel surface may have

shadows, streaks, or stains

Brush-Off

SSPC SP 7 NACE 4 Removal of loose mill scale, rust, and paint

Blast

(loose paint can be removed with dull putty

knife)

Pickling

SSPC SP 8

Removal of mill scale and rust from steel

Near-White

SSPC SP

NACE 2 Removal of visible contaminants except that 5

Blast

10

percent of steel surfaces may have shadows,

streaks, or stains

Power Tool

SSPC SP

Removal of visible contaminants (surface is

Cleaning

ll

comparable to SSPC SP 6, also provides

profile)

6.5.2

Standards for Cleaned Nonferrous Metals. No industry

standards describe the degree of cleaning of nonferrous metals,

and previously painted non-steel substrates.

6.5.3

Previously Coated Surfaces. When the surface to be

painted is an old weathered coating film (that is, surface

preparation will not include removal of the old coating), ASTM

visual standards should be used for chalk, mildew, and dirt

removal. In general, a minimum chalk rating (ASTM D 4214,

Evaluating Degree of Chalking of Exterior Paint Films) of 8

should be required for chalk removal, a minimum mildew removal

rating (ASTM D 3274, Evaluating Degree of Surface Disfigurement

of Paint ) of 8 (preferably 10) should be required for mildew

removal, and an ASTM D 3274 rating of 10 should be required for

dirt removal. Consideration should be given to requiring

preparation of a job-specific standard (as described in

par. 6.5.1.2) when large jobs are contracted. This standard

should cover removal of loose material, chalk, and mildew, as

well as feathering of edges, and other requirements of the

contract specification.

80

Previous Page

Previous Page