MIL-HDBK-1164

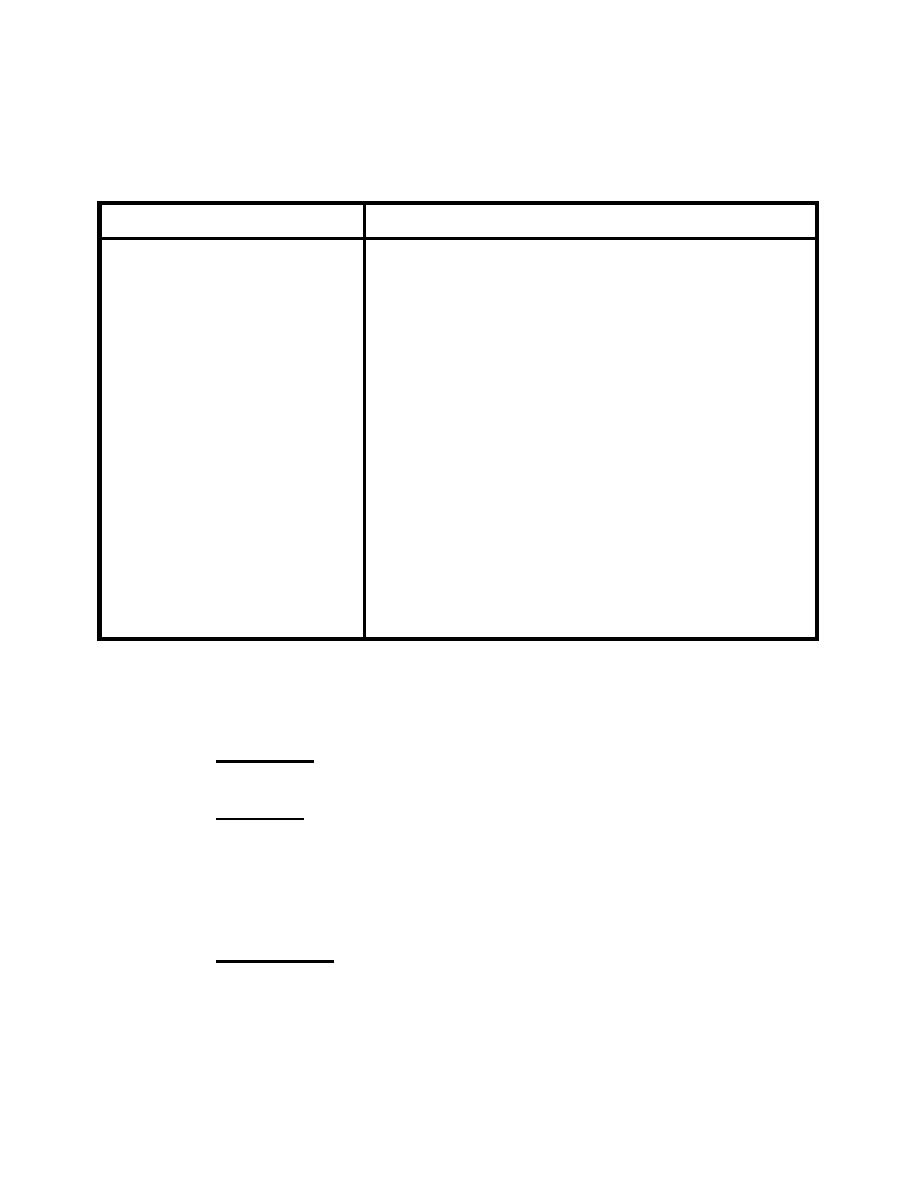

Table 21 (Continued)

Inspection

Action

Instruments

Check indicators. Indicators should return to zero

when engine is not running.

Battery and voltmeter

Check that battery has not run down and retains

sufficient charge.

Accessories and belts

Check for signs of wear.

Electrical Wiring

Inspect wire integrity (no frayed or charred wires; no

loose wires).

Air cleaner and breather

Look for obstructions or clogs.

caps

Fuel filters

Be sure filters are not clogged or dirty. Change or

clean as required or at regular intervals.

Engine controls

Controls should move freely. Check for binding,

sticking, etc.

Leakage

Look for oil and coolant leaks.

Gear oil levels

Check level.

Additional O&M information for internal combustion engines is provided in

par. 2.1.4. Overhaul and tune-up type maintenance is the motor pool's responsibility.

6.7

Accessories. Accessories include belt drives, gear drives, variable speed

drives, and couplings that connect the driver to the pump.

6.7.1

Belt Drives. Two types of belts are used for belt drivers: V-belts and flat

belts. Maintaining proper tension and alignment of belt drives ensures long life of belts

and sheaves. Incorrect alignment causes poor operation and excessive belt wear.

Inadequate tension reduces the belt grip and causes high belt loads, snapping, and

unusual wear. Keep belts and sheaves clean and free of oil, which deteriorates belts.

Replace belts as soon as they become frayed, worn, or cracked.

6.7.1.1

Installing Belts. Before installing belts, replace worn or damaged

sheaves. Check alignment with a straight edge or string, and make the necessary

corrections to keep the pulleys in line. Loosen the belt tensioning adjustment enough

116

Previous Page

Previous Page