MIL-HDBK-1164

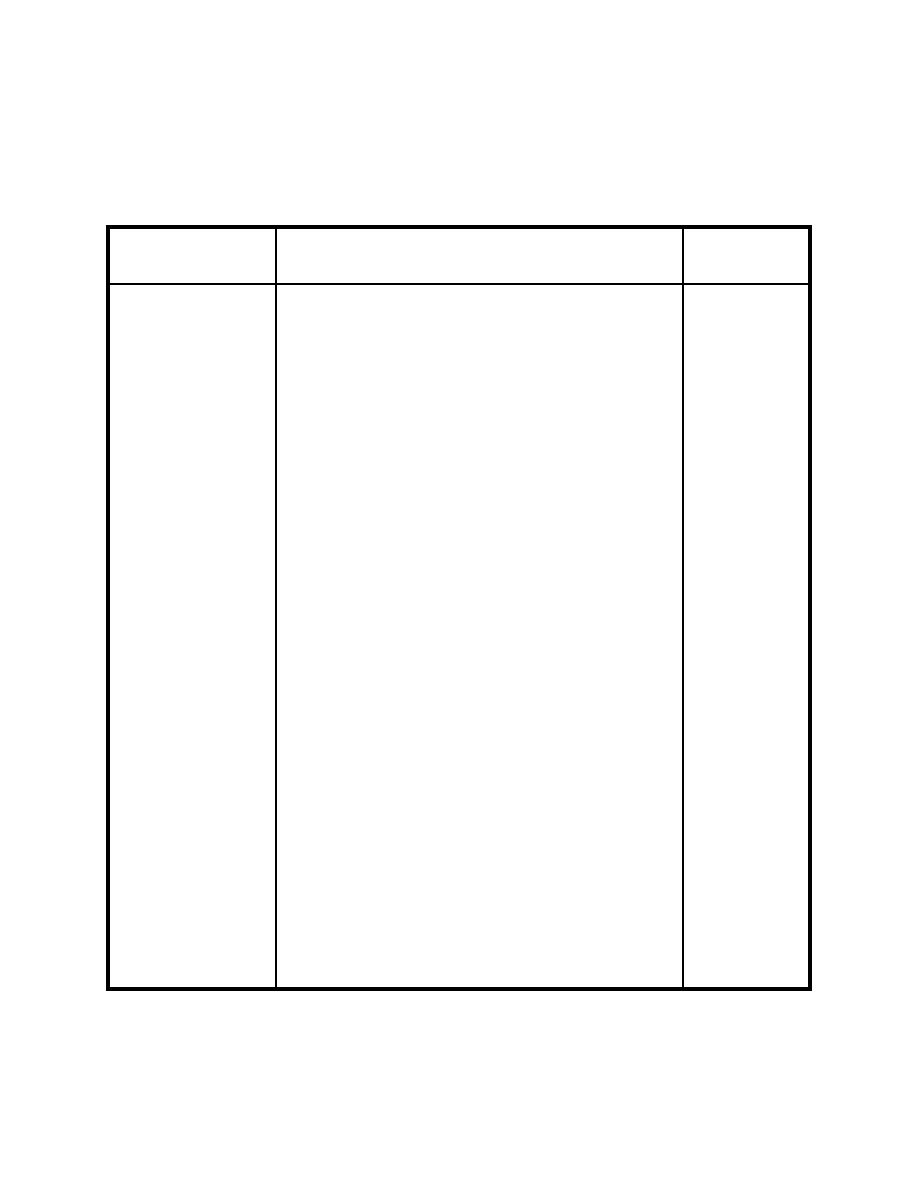

Table 28

Maintenance Checklist for Transmission Systems

Inspection

Action

(1), (2)

Mechanical

Direct links--make certain pulley, drums, cable,

Q

etc., work freely and are not corroded; clean,

lubricate, and adjust.

Hydraulic

Pressure links-blow down pressure lines, make

SA

certain there are no restrictions; correct adverse

conditions.

Pneumatic

Transmitter

Flush liquid side of air-relay units; clean; if

D

necessary check diaphragm; check air-input

orifice, clean, blow out moisture traps.

Disassemble, repair, or renew as necessary.

V

Link

Check connecting tubing for condition; check

SA

nozzle system for leaks.

Electrical

M

Transmitter

Service transmitter; check signal interval length

over instrument range.

Check mercury switch and magnet; adjust as

Q

necessary.

Remove old lubricant, add new.

SA

Link

Check wires whenever necessary.

V

Indicators

Clean cover and glass of gages.

SA

Check zero setting and calibration

A

Mechanical

Inspect and service as for transmitter.

Q

transmission

Hydraulic

Vent air from mercury wells; check pulley shaft,

W

transmission

chain, cam, stuffing box, and other parts.

Check mercury wells; add new mercury if

A

necessary; clean or replace mercury if

necessary.

151

Previous Page

Previous Page