MIL-HDBK-1164

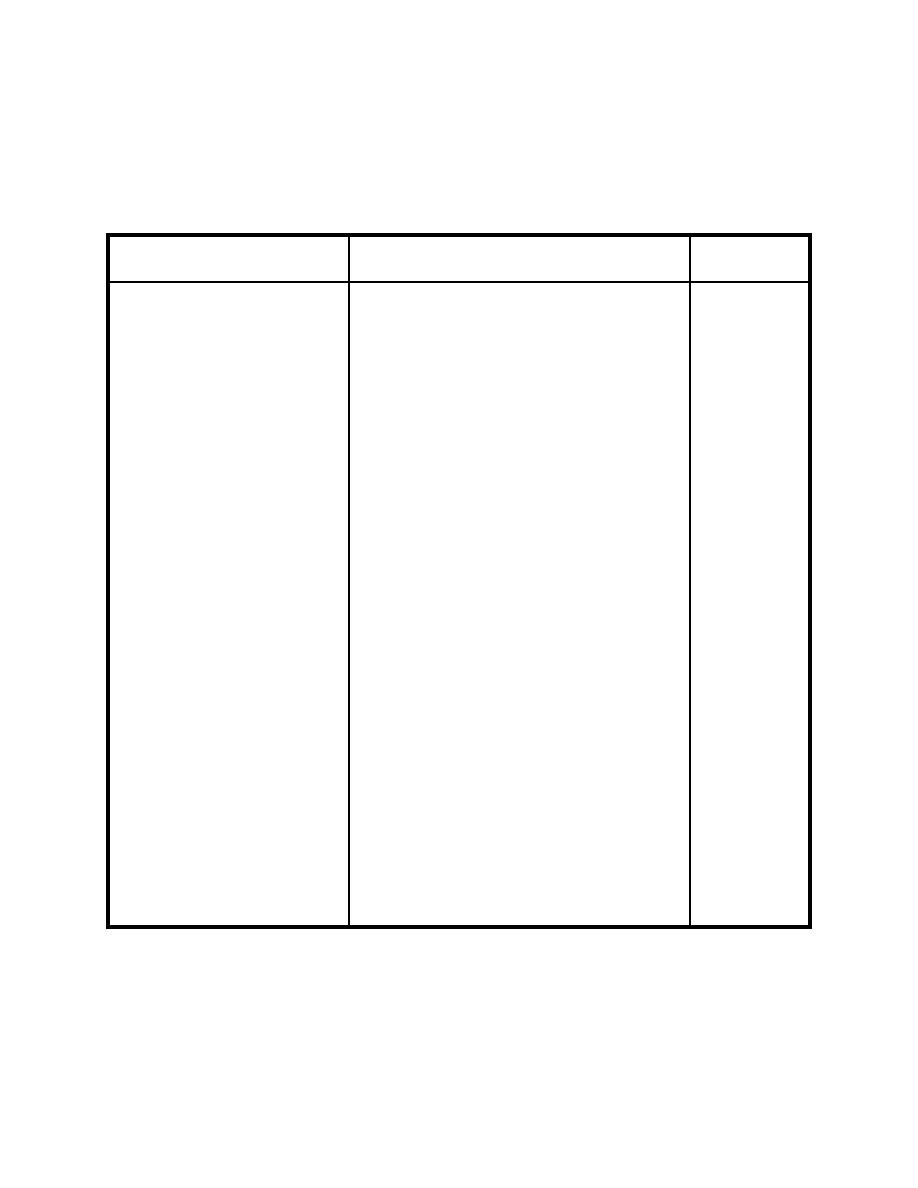

Table 39

Maintenance Checklist for Compressors

Inspection

Action

(1), (2)

M

Intake Filters

Inspect the compressor filter. Inspect

more frequently (daily) in areas with

severe dust. (3)

Clean or replace as indicated for each

SA

filter type.

Impregnated paper filter

Replace when dirty.

Cloth filter

Wash with soap and water, dry, and

reinstall. Keep spare filter on hand for

use when main filter is being washed.

Wire mesh and oil-bath

Clean with a standard solvent; reoil or

filter

drain and refill oil bath; reuse.

Bearings

Inspect bearings and lubricate if

D

necessary. Most compressors have

bearings that require oiling.

Crankcase reservoir

Examine the reservoir dipstick or sight

D

glass for oil level. Keep reservoir full

but do not overfill as excess oil can lock

up or damage compressor. (4)

Change compressor oil when

Q

necessary. If there are filters in the oil

system, change these regularly as well.

Drip-feed oiler

Check drip rate.

D

Force-feed oiler

Check pressure.

D

Grease fittings

Ensure fittings are greased.

Q

Cylinder or casing fins

Clean with compressed air or vacuum to

W

ensure proper cooling of the

compressor.

202

Previous Page

Previous Page