UFC 3-240-13FN

25 May 2005

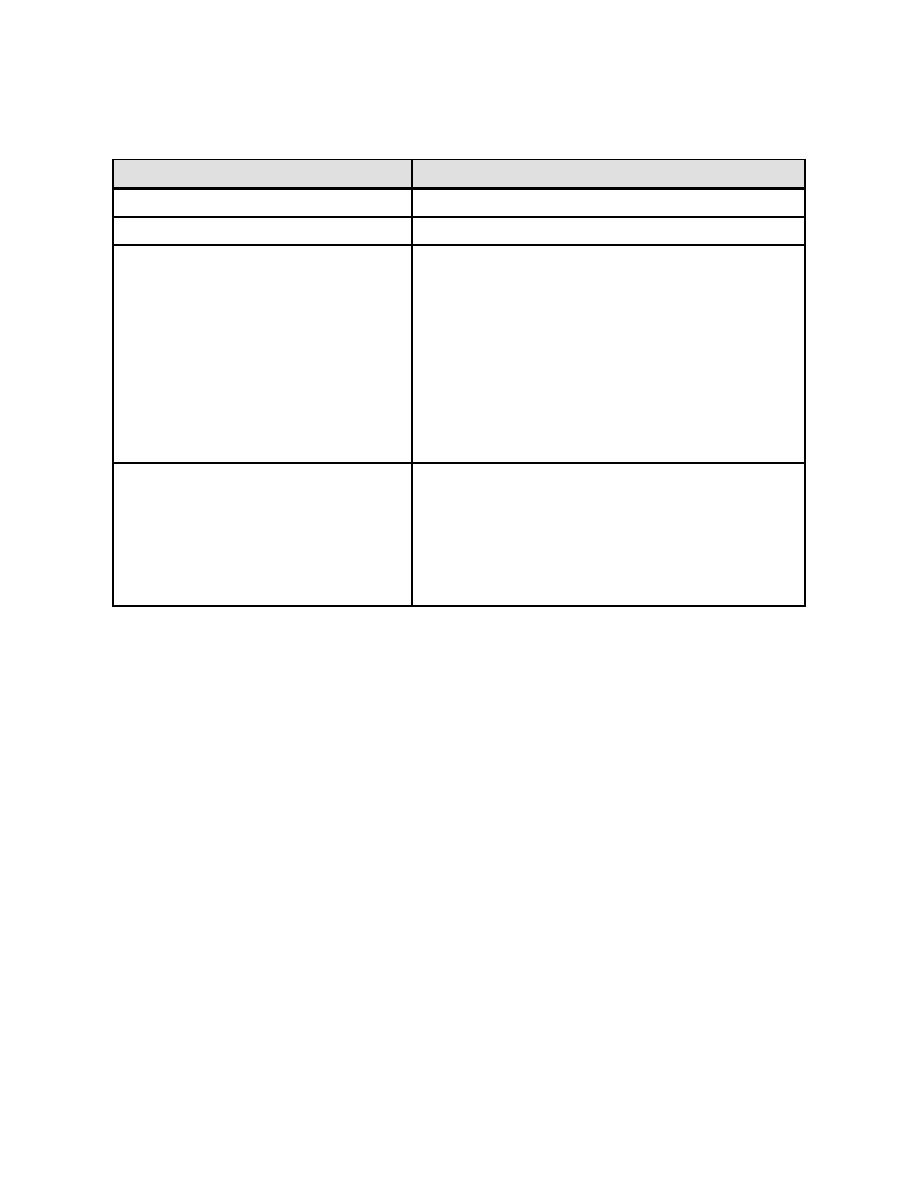

Table 3-18. Treatment Guidelines for Low-Pressure Steam

Boiler

Guidelines

Cast iron

Not treated

Less than 334 W (10 hp)

Not treated

1. External treatment: softening.

2. Internal treatment: precipitating or

solubilizing scale inhibitor, sulfite, tannin

derivatives, filming surfactant, caustic

supplement if necessary, neutralizing amine.

Boiler with 95% condensate return

3. See Tables 3-19 through 3-20.

Or

4. Treat same as closed hot water (see

Chapter 5).

1. External treatment: softening.

2. Internal treatment: precipitating or

solubilizing scale inhibitor, sulfite, tannin

Boilers with less than 95%

derivatives, filming surfactant, caustic

condensate return

supplement if necessary, neutralizing amine.

3. See Tables 3-19 and 3-20.

3-3.8

Treatment Guidelines for Medium- and High-Pressure Steam.

Treatment of medium- (110 to 2062 kilopascals [16 to 299 pounds per square inch

gauge]) and high-pressure (2068 to 6205 kilopascals [300 to 900 pounds per square

inch gauge]) boilers is similar and is described in Table 3-19. Treatment can include

either a precipitating (i.e., phosphate) or a solubilizing (i.e., phosphonate or polymers)

approach to scale control. Sulfite is used to control pitting due to oxygen, and a

neutralizing amine is used to control pH in the condensate system. Sometimes raising

pH in the boiler water requires a supplemental source of alkalinity. Usually this source is

caustic soda, but it can also be sodium carbonate (soda ash). Boilers operating

between 4137 to 6205 kilopascals (600 to 900 pounds per square inch gauge) will

sometimes use erythorbic acid or specialty volatile oxygen scavengers or amines (i.e.,

hydrazine, DEHA, carbohydrazide, hydroquinone or methylethylketoxime) as oxygen

scavengers in boiler water. The volatile compounds can also scavenge oxygen in a

condensate system. Refer to paragraph 3-2.7 for a description of condensate corrosion

control.

79

Previous Page

Previous Page