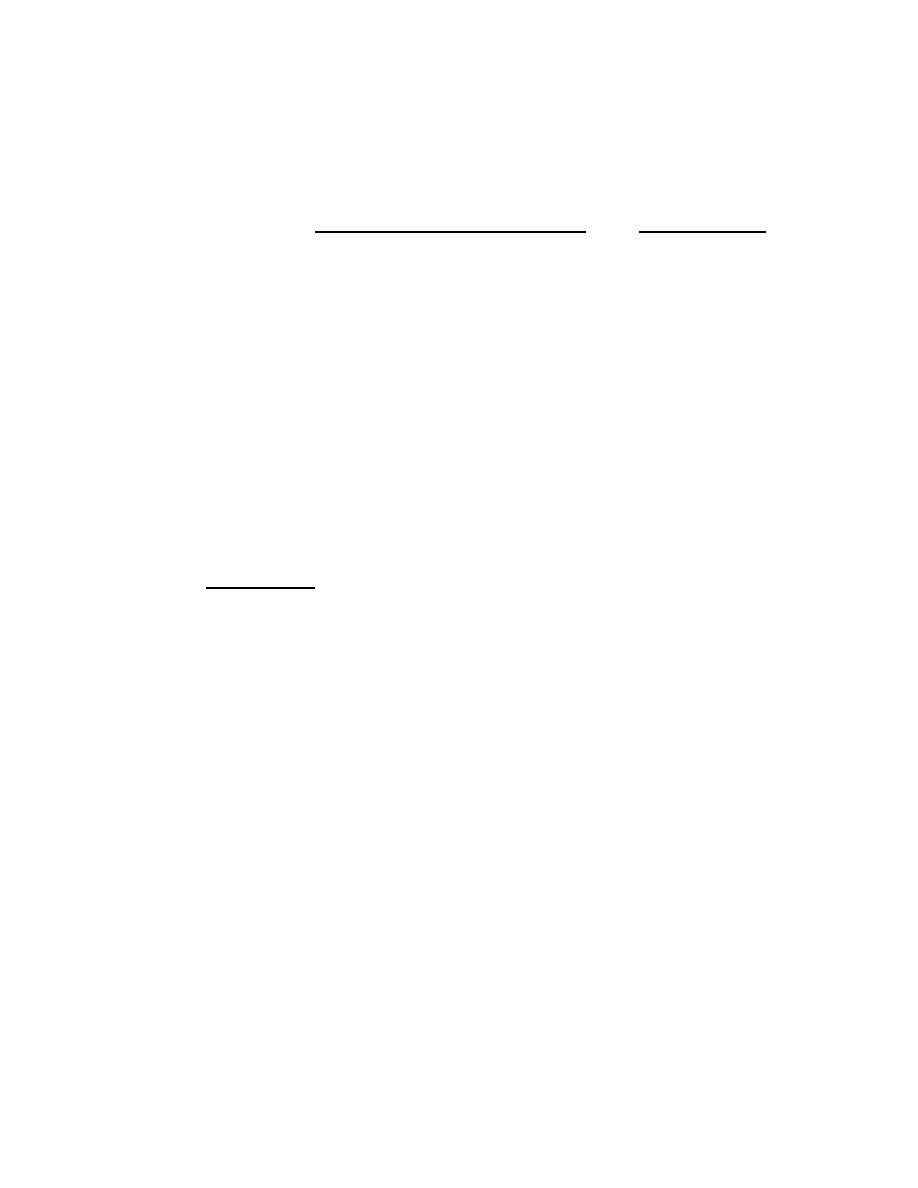

MIL-HDBK-1003/6

Table 4

Maximum Flue Gas Velocities (Feet Per Second) in Convection Sections for

Coal, Wood or Solid Waste Boilers

+)))))))))))))))))))))))))))))))))))))))))))))))))))))))))))))))))))))))))))),

*

*

Single Pass

Multi-Pass

*

*

Water Tube

Water

Tube

*

*

Solid

*

*

Coal

Wood

Waste

Coal

*

*

* Pulverized coal

*

50

60

*

*

*

* Underfeed stoker

75

60

*

*

*

* Spreader stoker

60

50 (1)

50

*

* traveling grate

*

*

*

* Spreader stoker

60

50

50

* traveling grate

*

*

*

* Traveling grate

*

75

60

* (front gravity feed)

*

*

*

* Solid waste

*

30

.))))))))))))))))))))))))))))))))))))))))))))))))))))))))))))))))))))))))))))-

(1) If wood has sand, use 35 fps.

Plant Layout. The plant layout should be designed to reduce

3.6

maintenance time, and allow for easy operation of equipment.

Future situations to consider include:

a)

Tube cleaning

b)

Tube replacement

c)

Future expansion

d)

Conversion fuels

Tube replacement for firetube boilers typically requires a space in

front of the boiler which is equal to the boiler's longest length. If there

is a possibility of future conversion of firing equipment to another fuel,

provide space for the installation and operation of such equipment and for

local storage and handling of the new fuel. Enough room shall be provided to

accommodate all auxiliaries such as feed pumps, fuel pumps, condensate tank

water heaters, deairators, condensate receivers and other equipment normally

located in the boiler room.

15

Previous Page

Previous Page