MIL-HDBK-1165

initial capital cost of installing a recycling system can range

from approximately K to several hundred thousand, depending on

the technology employed.

5.3.1.2

Operation and Maintenance Procedures. The following

maintenance procedures can help conserve washrack water use:

a) A periodic check of equipment for malfunctions or

leaks is a simple but effective way to conserve washrack water.

b) If detergents are used, use high quality detergents

with superior cleaning power. This, combined with good

rinsability, will shorten the length of time required to clean

each vehicle or aircraft.

5.3.1.3

Retrofits. For existing wash facility equipment, there

are several low cost measures that are capable of saving

significant amounts of water.

a) Timers - useful in aircraft rinsing facilities, but

not for washrack units since each vehicle or aircraft must be

washed until sufficiently clean. The timing is different for

each run and should not be preset.

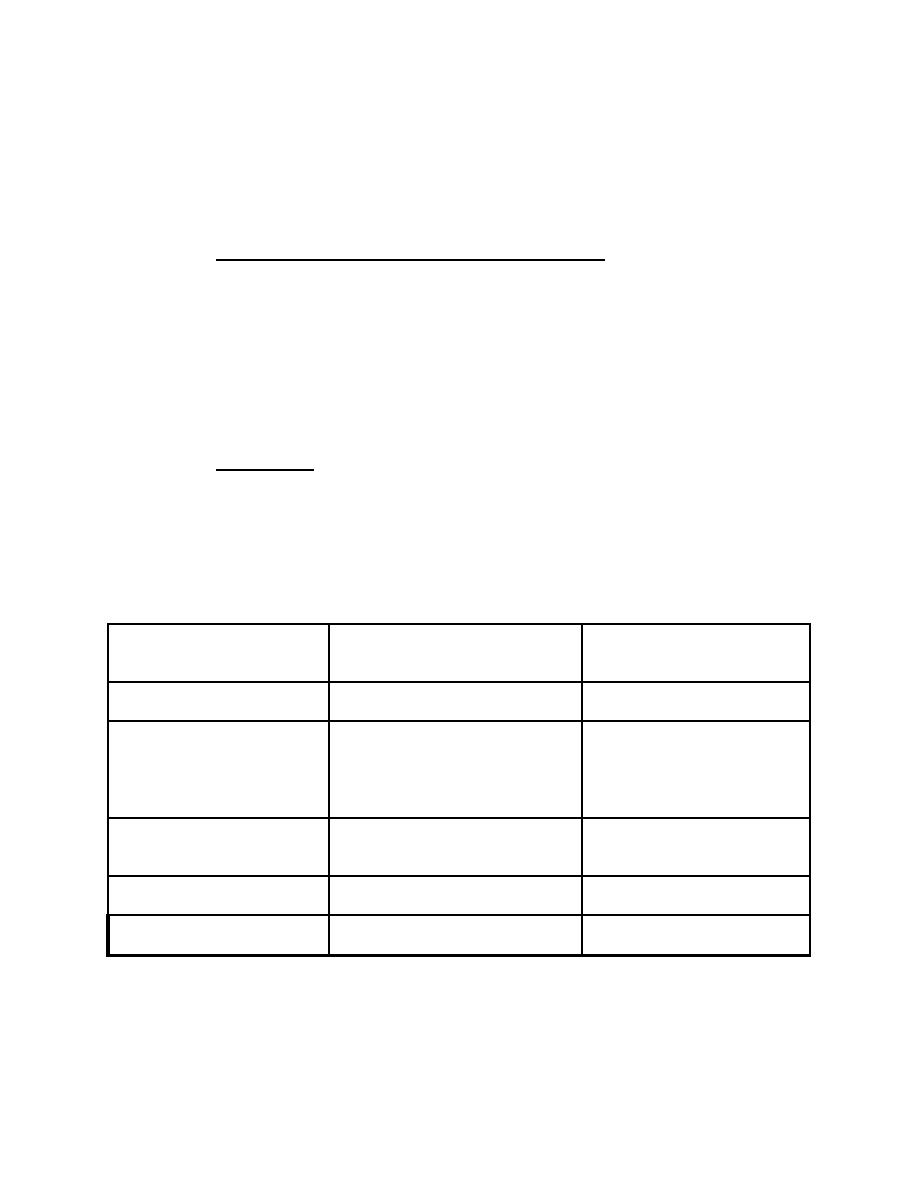

AVERAGE WASTEWATER

TYPE OF FACILITY

WATER REQUIRED

PER ITEM

PRODUCED

GALLONS

LITERS

GALLONS

LITERS

Aircraft Rinsing

1000-3000 3785-11350

1750

6625

(helicopter)

(helicopter and

Aircraft Washrack

200

760

aircraft)

Platform

(aircraft)

2000

7570

2500-3000 9460-11350

Automotive Vehicle

100-1000

380-3785

600

2270

Washrack

depending on size

Tracked Vehicle

1000-3000

3785-11350

2000

7570

Washrack

Automotive Vehicle

same as automotive

same as automotive

Maintenance

washrack

washrack

Figure 12

Washrack Water Requirements

39

Previous Page

Previous Page