UFC 4-150-06

12 December 2001

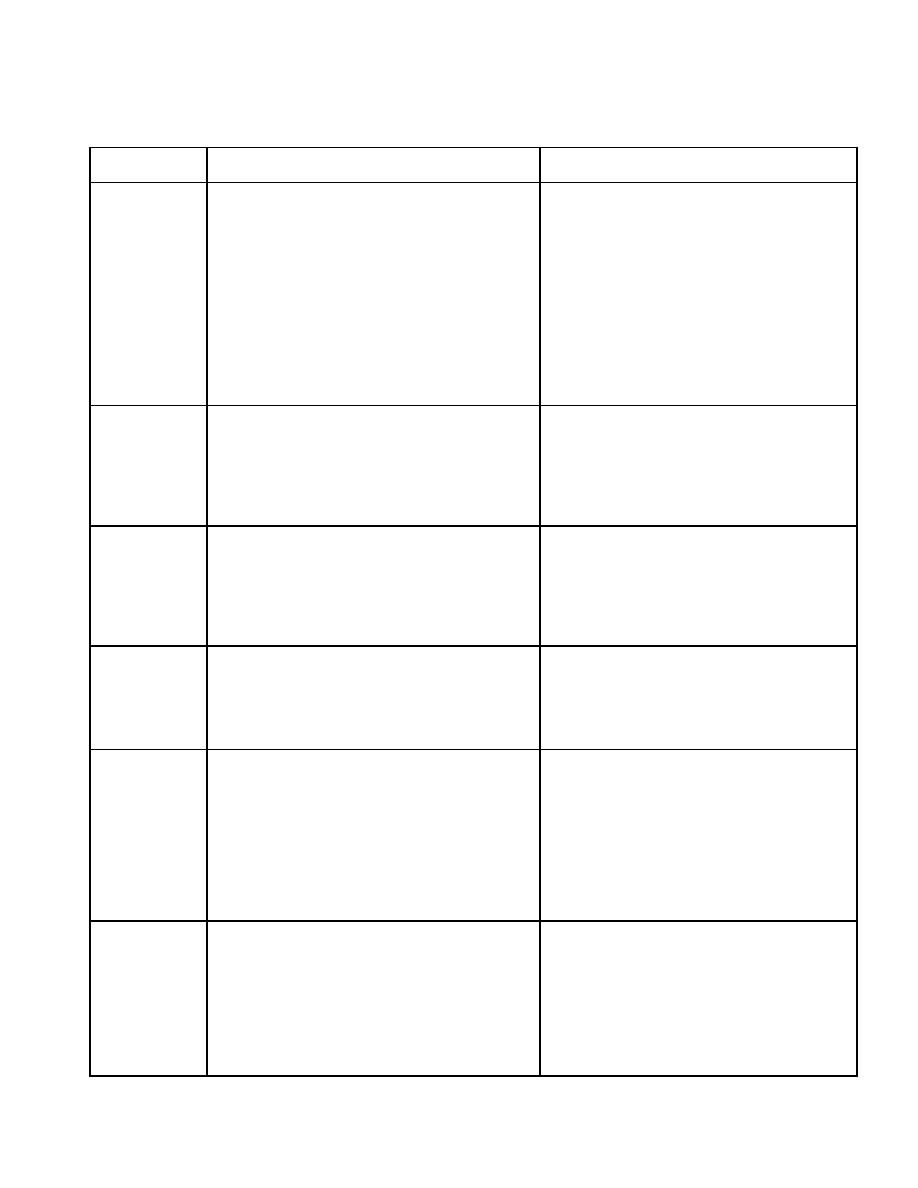

Table 5-11 Selection Factors for Berthing Arrangements

Berthing

Advantages

Disadvantages

System

Marginal

Solid fill supports deck loads without expensive

Costs per berth greater than for pier systems.

Wharf

Ratio of berthing space to length of

(Figure 5-15a)

Accessibility of entire upshore area for working

waterfront is low.

space, storage space, laydown operations, and

Berthing length is limited to length of face of

traffic circulation adds to the utility of the wharf

wharf, unless mooring dolphins are used to

as compared to pier or offshore wharf systems.

extend usable length.

Permits utilization of surplus fill material.

Suitable for sites where pier cannot be

projected out from shore and where dredging of

a recessed basin for piers would be expensive.

Also suitable where the navigation channel is

too narrow to permit maneuvering into finger

piers.

Square Pier

Solid fill supports deck loads without expensive

Economy depends on availability of

(Figure 5-15b)

inexpensive fill.

Upshore area is accessible for storage and

The requirements for fill or piling are great

traffic circulation.

compared to the usable space provided on

Side-berth accommodations add to linear feet

the deck.

of berthing accommodations.

Permits utilization of surplus fill material.

Rectangular

Length of accommodation for a given length of

In some bottom formations, any considerable

Pier and Slip

shoreline is great. In general, this system has

later dredging of slips may be hazardous.

(Figures 5-15c,

the lowest relative cost per berth.

Space between slips is limited, and adds to

15d, and 15f)

the density of navigation traffic.

Reduces width of navigation channel.

Cargo handling is restricted unless pier has

at least 6 acres per berth.

Angle Pier and

Layout is advantageous compared to

Construction is more difficult and expensive

Slip

rectangular pier-and-slip system where

than that for rectangular pier-and-slip system.

(Figures 5-15e

navigation channel is too narrow for

Corners of the pier are waste space where

and 5-15g)

perpendicular pier layout. Currents or

cargo-handling equipment cannot work.

prevailing winds may also dictate the use of

angle piers.

Offshore

Layout adaptable to many types of construction

When a single causeway is used, craft along

Marginal

methods, including floating wharfage.

the causeway create loading and unloading

Wharves

Moorings for shallow-draft craft may be

and traffic problems.

(Figures 5-

provided along the sides of the causeway.

Usually requires separate moorings,

15h, 5-15i, and

When multiple causeways are used, a movable

supported by the wharf structure, because a

5-15j)

section can be provided to give access to

relatively large area of the wharf structure is

space between causeways.

not tied to shore anchorages.

Suitable along rocky shores.

Suitable where water of adequate depth is

located at large distance offshore.

Floating

Floating wharves can be moored in water too

Maintenance is high. (Maintenance of steel

Wharves

deep for pile driving.

floating wharves is higher than that of

Pontoon or prefabricated sections can be used.

concrete floating wharves.)

Equipment can be quickly assembled, moved,

Not suitable for heavy craft nor in exposed

and replaced.

locations without heavy anchorage

requirements.

Difficult to maintain alignment in heavy tide

range.

Restricted cargo-handling capability.

5-59

Previous Page

Previous Page