UFC 4-150-08

01 April 2001

Berths providing Mooring Service Type III are especially high

priority, because the ships under repair at these piers and wharves

cannot get under way in case of an approaching storm.

High capacity fittings secure a larger portion of a mooring load at a

given facility, and should be assigned higher priority (i.e. a Special

Mooring Bollard 'A' holds more load than a 30-inch cleat, so the

bollard is assigned a higher priority).

Older facilities not previously pull tested are more likely to suffer

from structural deterioration and should be assigned higher priority.

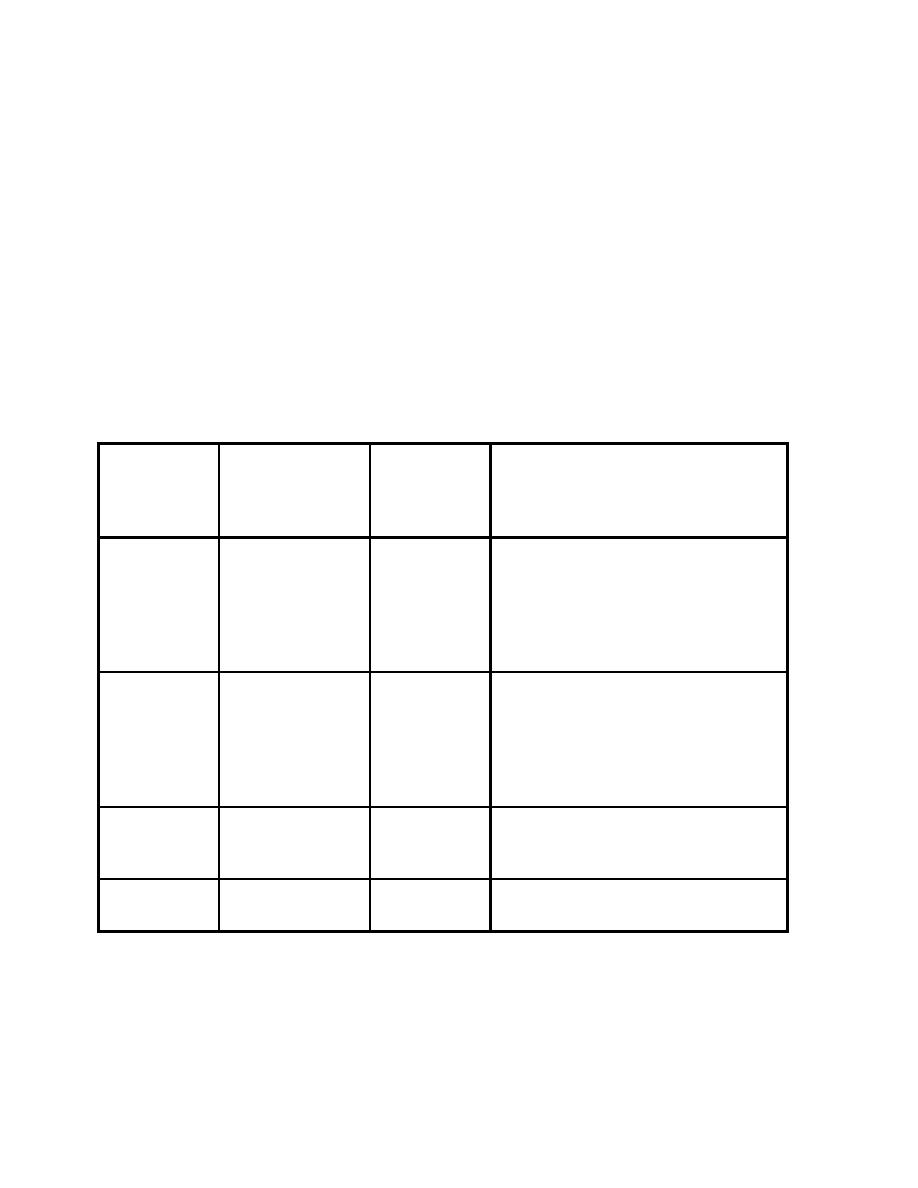

Testing recommendations are shown in Table B-1.

Table B-1. Pull Testing Interval Recommendations

DESCRIPTION

HARDWAR

TESTING

MINIMUM

INTERVAL

% OF

E

PRIORITY

HARDWAR

E

HIGH

12 years

20%

For older and very important

facilities, up to 100% of fittings can

be tested. If any of the tested

fittings fail, then testing should be

expanded to include a higher

percentage of fittings.

MEDIUM

18 years

10%

For older or very important

facilities, up to 50% or more of

fittings can be tested. If any of the

tested fittings fail, then testing

should be expanded to include a

higher percentage of fittings.

LOW

TBD

TBD

A responsible authority should

determine what level, if any, pull

testing is required.

MOORING

During

100%

All anchors are pull tested during

installation

initial installation.

SECTION 3 QUALIFICATIONS

3-1

Personnel. If contracted, the testing of mooring hardware should be

conducted under the direct supervision of a Registered Professional Engineer (P.E.)

who has experience in the design and inspection of marine structures. At a minimum

the supervising engineer (P.E.) should be on site and involved in the testing to assess

B-3

Previous Page

Previous Page