Thus all the major penetrations specified, the entranceway, the viewport

penetrations, and the inlet and outlet nozzles require reinforcement.

(4) Inlet and Outlet Nozzles. The inlet and outlet nozzles are

designed to meet the specifications of paragraphs AD-520, 540.1, 540.2(a) and

Figure AD-540.1(b) as described in the previous example. The geometry of

these nozzles is shown in Figure 2-22. Here the notation [theta] is the

angle that the sectioning plane makes with the plane containing the

longitudinal axis of the cylinder.

(5) Viewport Penetration in Center of End Cap. Here, as before,

it was decided to use the type of viewport as portrayed in Figure 3-6 in

Chapter 3. It will again be assumed that a 10.0 inch diameter penetration is

required. The development of this reinforcement in the center of the

spherical portion of the end cap is exactly as before and the details of this

reinforcement are shown in Figure 2-23.

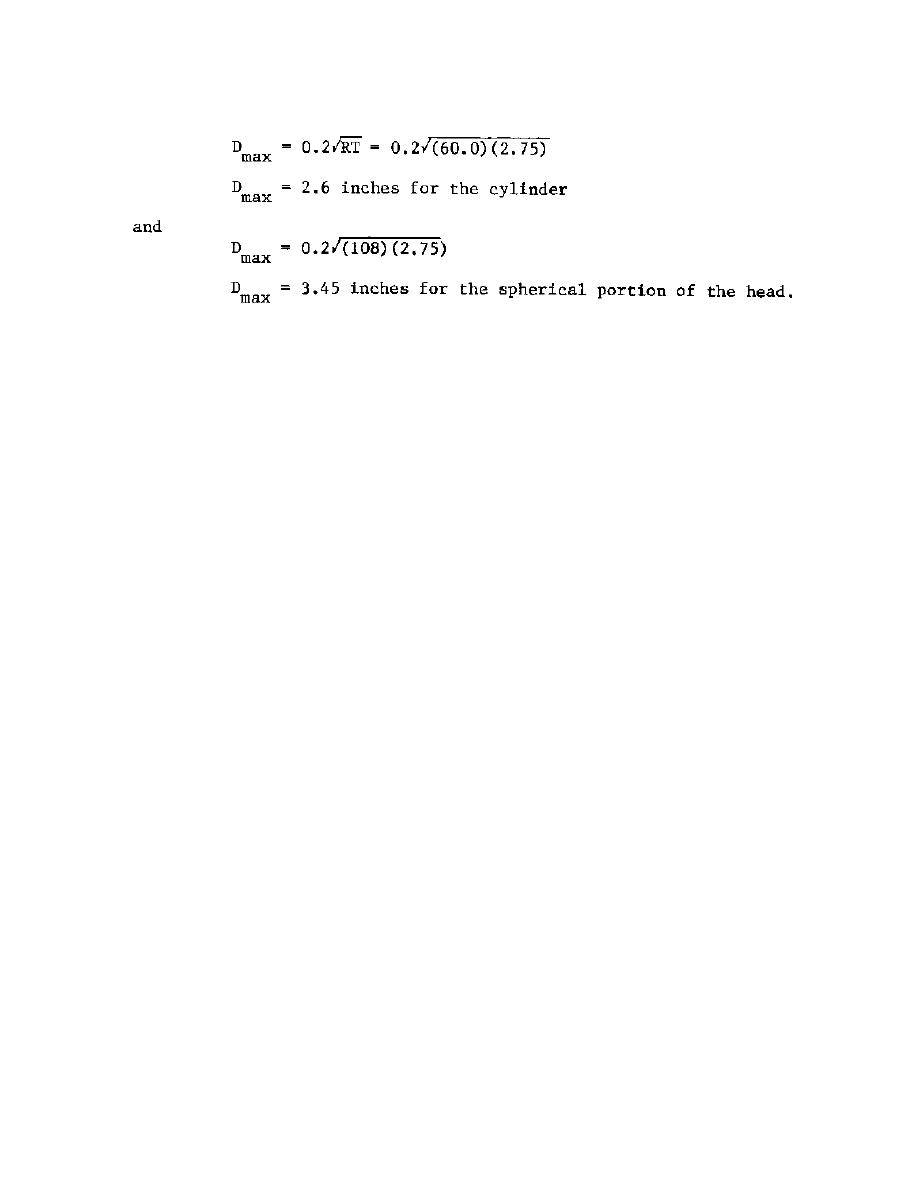

(6) Entranceway. It is required to have a 40.0 inch inner

diameter entranceway in the center of the other end cap of the cylinder.

The

area to be replaced by some sort of reinforcement is

Ar = dtr = (40.0)(2.72) = 108.8 in.2

with one-half or 54.4 in2 on each side of the centerline of the opening. It

is decided to use, as reinforcement, an inserted, thick-walled cylinder with

inner diameter equal to 40.0 inches. Section VIII, Division 2, gives no

guidance for the design of such a reinforcement.

However, Section VIII,

Division 1, can be helpful in this case. Paragraph UG-40, "Limits of

Reinforcement" states that the limits of reinforcement measured normal to the

vessel wall shall conform to the contour of each surface limited to a

distance from each surface to two and one-half (2-1/2) times the nominal wall

thickness. In this case

Limit = 2.5 x 2.75 = 6.85 inches from each surface.

Choosing a 4.0 inch wall thickness cylinder, the overall height of the

cylinder is

(4.0)(h) = 54.4 + (4.0)(2.75) = 54.4 +11.0

65.4

Previous Page

Previous Page