8.04 psi per 100 feet of pipe. The velocity for 5-inch pipe is on the high

side at 9.63 feet/second, while the pressure drop is still lower at 2.55 psi

per 100 feet of length. At this point it would be necessary to check on

costs of 4-inch and 5-inch pipe and components, and the output pressures of

candidate pumps. Complete calculations would be made for both systems to

provide a basis for selection. Using only the 5-inch pipe size for this

example, Figure 5-2, shows that the equivalent 5-inch pipe lengths for the

three fittings are: (1) for the globe valve - 140 feet, (2) for the standard

elbow - 13 feet, and (3) for the angle valve - 70 feet. The pressure drop

for the equivalent length of 343 feet is 2.55 times 3.43 or about 9 psi.

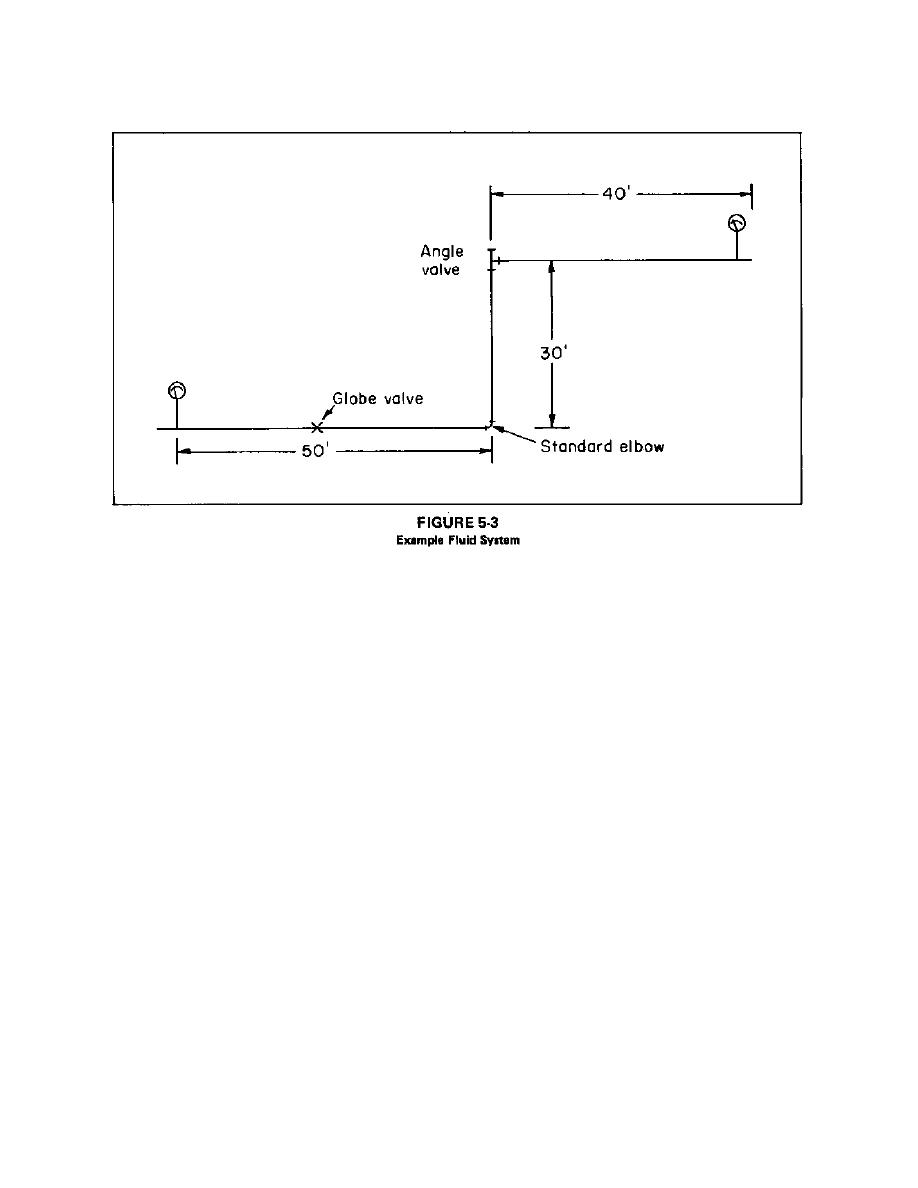

(6) Approximation for Oxygen, Low Flow. Let the maximum required

flow in the system shown in Figure 5-3 equal 100 scfm of oxygen from a

manifold with a pressure of 250 psia. Because the flow required is low and

excessive velocity of oxygen through valves can cause a fire hazard, assume

that the total pressure drop is 10 percent of the inlet pressure, or 25 psi.

Using 250 psia as the effective system pressure, and using the weight density

of oxygen at atmospheric pressure from Table 5-5, the weight density of

oxygen at 250 psia is calculated to be 1.41 pounds/feet3. This is

approximately 2.4 times the weight density of air in Table 5-10 (0.596

pounds/feet3). The required flow of oxygen (100 scfm) can be provided at

250 psia with a flow of about 5.9 feet3/minute (using Equation (3)).

Referring to Table 5-10, it

Previous Page

Previous Page