UFC 3-570-06

JANUARY 31 2003

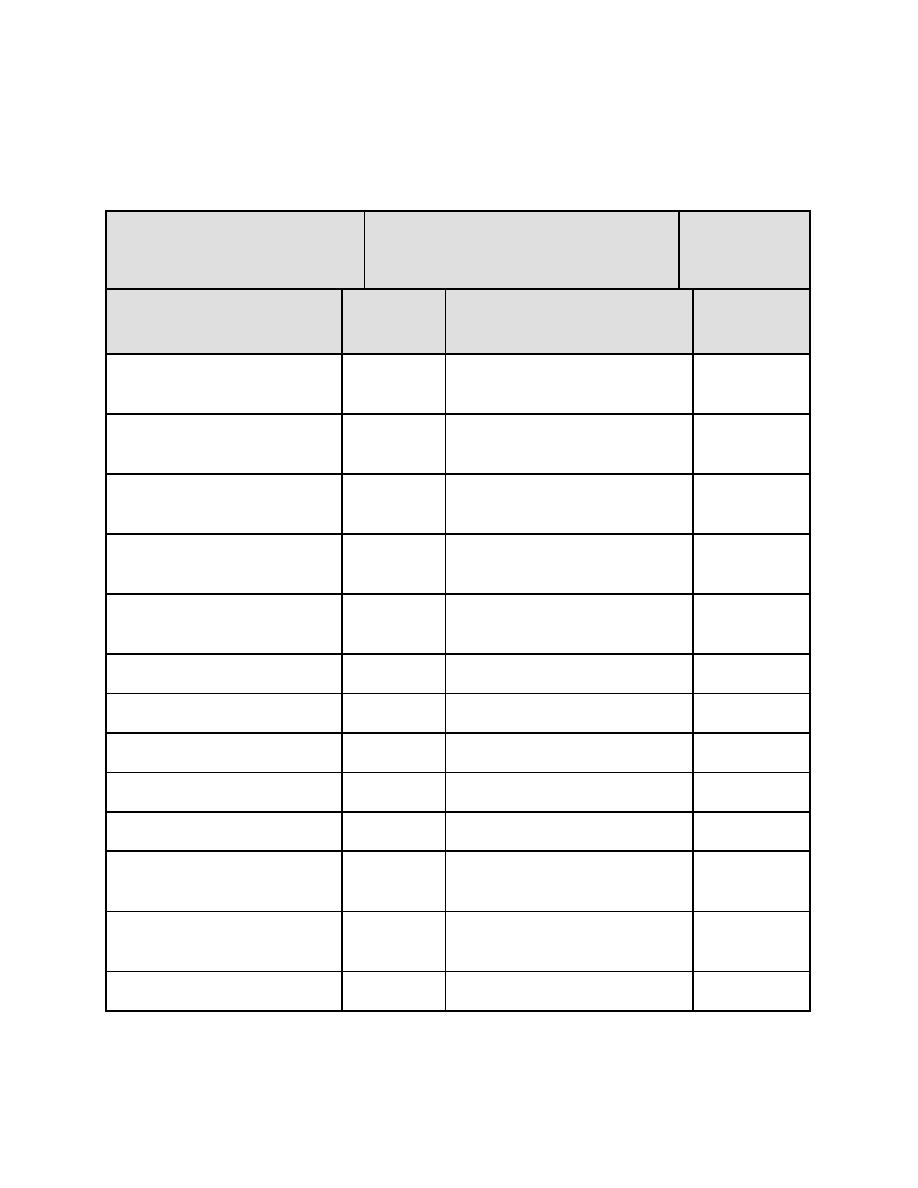

Table 2-4. Current Requirements for Cathodic Protection of Coated Steel

MILLIAMPERES

PER SQUARE METER (FOOT)

STRUCTURE

BARE

COATED

COATING

EFFICIENCY

Pipeline, epoxy or other high 10.76(1)

0.0100.054(0.0010.005)

99.5 - 99.9

performance coating

Pipeline, reinforced coal tar

10.76(1)

0.0540.269(0.0050.025)

97.5 - 99.5

or asphalt enamel

Pipeline, grease coating with 10.76(1)

0.5381.615(0.050.15)

85.0 - 95.0

wrapper

Pipeline, asphalt mastic "

10.76(1)

0.0010.005(0.0010.005)

99.5 - 99.9

thick

Pipeline, old asphalt or other 10.76(1)

0.5383.767(0.050.35)

65.0 - 95.0

deteriorated coating

Pipeline, old paint coating

10.76(1)

1.0760.522(0.100.30)

70.0 - 90.0

Tank bottoms

32.29(3)

0.53821.529(0.052.00)

33.3 - 98.3

Tanks for cold potable water 32.29(3)

0.53821.529(0.052.00)

33.3 - 98.3

Tanks for cold sea water

53.82(5)

0.53843.056(0.054.00)

20.0 - 99.0

Hot potable water tanks

53.82(5)

0.52232.292(0.303.00)

40.0 - 94.0

Steel sheet piling fresh water 53.82(5)

1.07616.146(0.101.50)

70.0 - 98.0

side

Steel sheet piling sea water 53.82(5)

1.07621.529(0.102.00)

60.0 - 98.0

side

Steel sheet piling soil side

21.5 (2)

0.2154.304(0.002-0.40)

80.0 - 99.0

2-6

GALVANIC CATHODIC PROTECTION. In galvanic anode systems, the

2-27

Previous Page

Previous Page