MIL-HDBK-1110

b) Air-oxidizing coatings have limited solvent

resistance. They continue to oxidize and cross-link after

initial drying and curing. Thus, with time, they become harder,

more brittle, and less soluble in solvent. That is, they become

more like thermosetting coatings and are harder to recoat and

maintain.

c) Although alkyds have long been the most widely used

type of protective coating, their use is dropping rapidly because

of difficulties in preparing formulations with: low VOC content,

a brushable viscosity, and good film properties. Exempted

halogenated hydrocarbons are presently being used to produce

limited low-VOC alkyd formulations, but this exemption is

expected to be withdrawn in the near future.

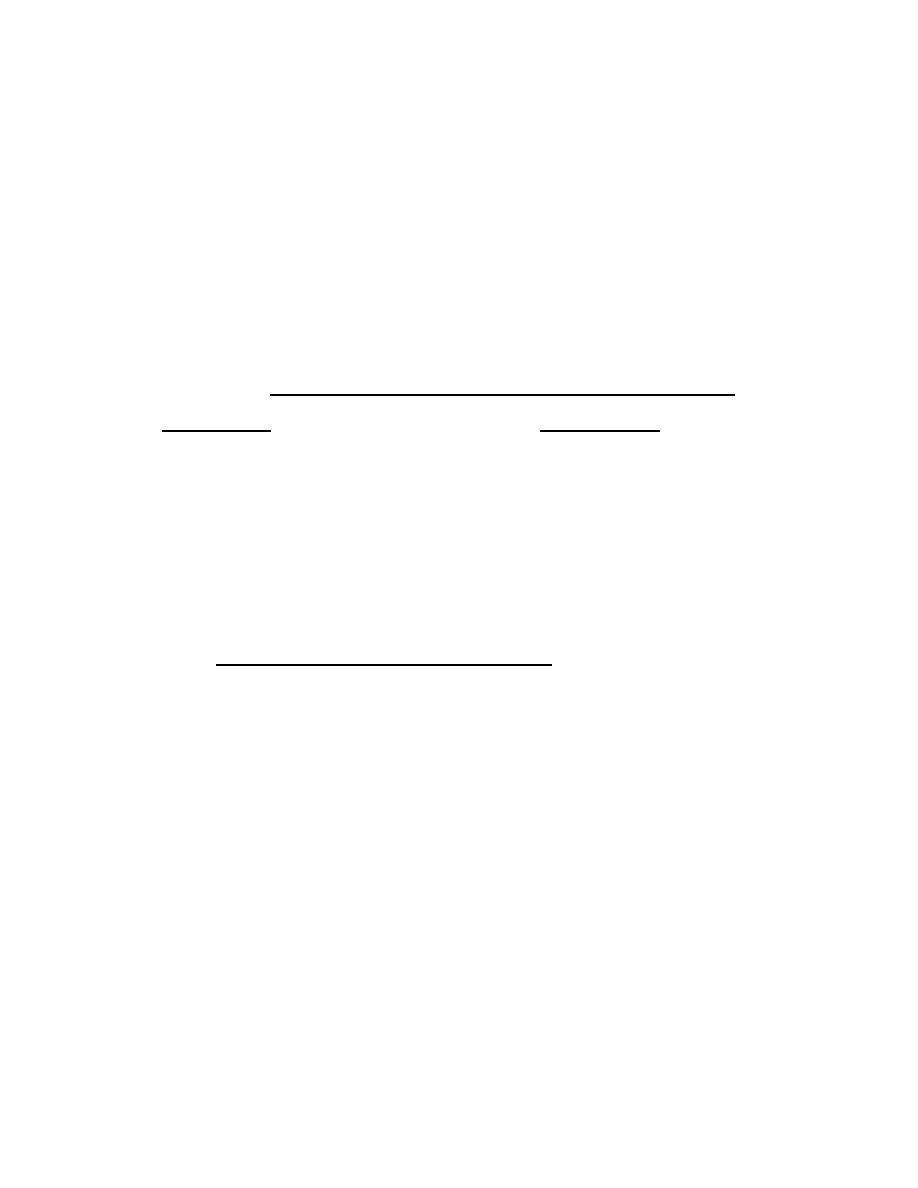

Alkyd and Most Other Air-Oxidizing Coatings

Advantages

Limitations

Easy

to apply/repair/topcoat

Relatively high in VOCs

Good

initial flexibility possible

Poor performance in severe

Good

surface wetting/adhesion

environment

Good

gloss retention

Poor chemical/solvent

resistance

Relatively inexpensive

Poor immersion resistance

Based on renewable source

Poor alkali resistance

Poor heat resistance

Become brittle with extended

aging

2.3.2

Water Emulsion (Latex) Coatings. Water emulsion

coatings, commonly called latex coatings, have been successfully

used for many years to coat wood and masonry structures. The

porous nature of their films allows water vapor to pass through

them, i.e., they are breathing. This porosity reduces their

durability on steel. Thus, much effort is being made to develop

more durable products because of the great advantages of their

low VOC contents and ease of application and clean-up. In

addition, water-emulsion coatings have excellent flexibility and

low cost, and are easily topcoated and repaired. Drawbacks

include poor solvent and heat resistance (as with all

thermoplastics), poor immersion resistance, and difficulty in

bonding to smooth oil/alkyd coatings and chalky surfaces. The

poor bonding is due to insufficient content of organic solvents

to soften and wet the binder in the existing paint film. Because

of this limited adhesion, it is necessary to sand smooth enamels

and/or use a surface conditioner before topcoating with latex

15

Previous Page

Previous Page