MIL-HDBK-1164

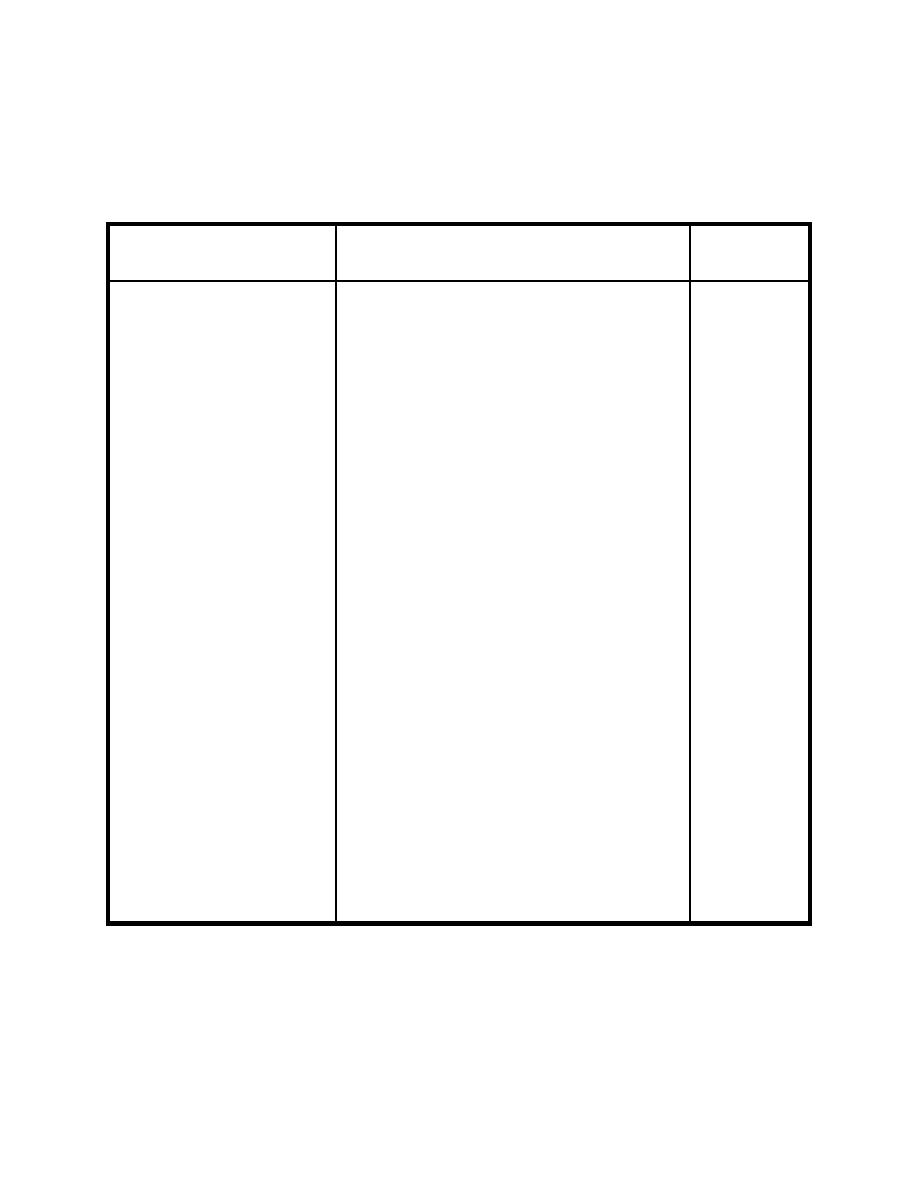

Table 14

Lubrication Schedule for Centrifugal-Type Pumps

Lubrication Point

Action Required

(1)

D

Grease-sealed packing

Check spring-loaded grease cup; refill as

gland

necessary; adjust spring tension to

maintain grease discharge through

packing at approximately 1 ounce per

day.

Guide bearing

Add grease through fittings provided.

M

Sealing water system

Check packing gland assembly; adjust

D

packing if excessive seal-water leakage is

noticed, allow 60 drops per minute with

pump running.

Check stuffing box for free movement of

SA

gland.

Hand oiler

According to Table 15.

Each shift

Solenoid oiler

Check that leads are connected; check

D

needle valve for clogging; adjust for 2 to

4 drops per minute; refill container as

necessary.

Sleeve bearing

Check bearing temperature; if too hot,

M

add lubricant.

Drain lubricant; wash wells and bearing

Q

with kerosene.

Universal joint coupling

Lubricate couplings and slip splines with

SA

fresh grease.

(1) D-Daily; W-Weekly; M-Monthly; Q-Quarterly;

SA-Semiannually.

90

Previous Page

Previous Page