MIL-HDBK-1164

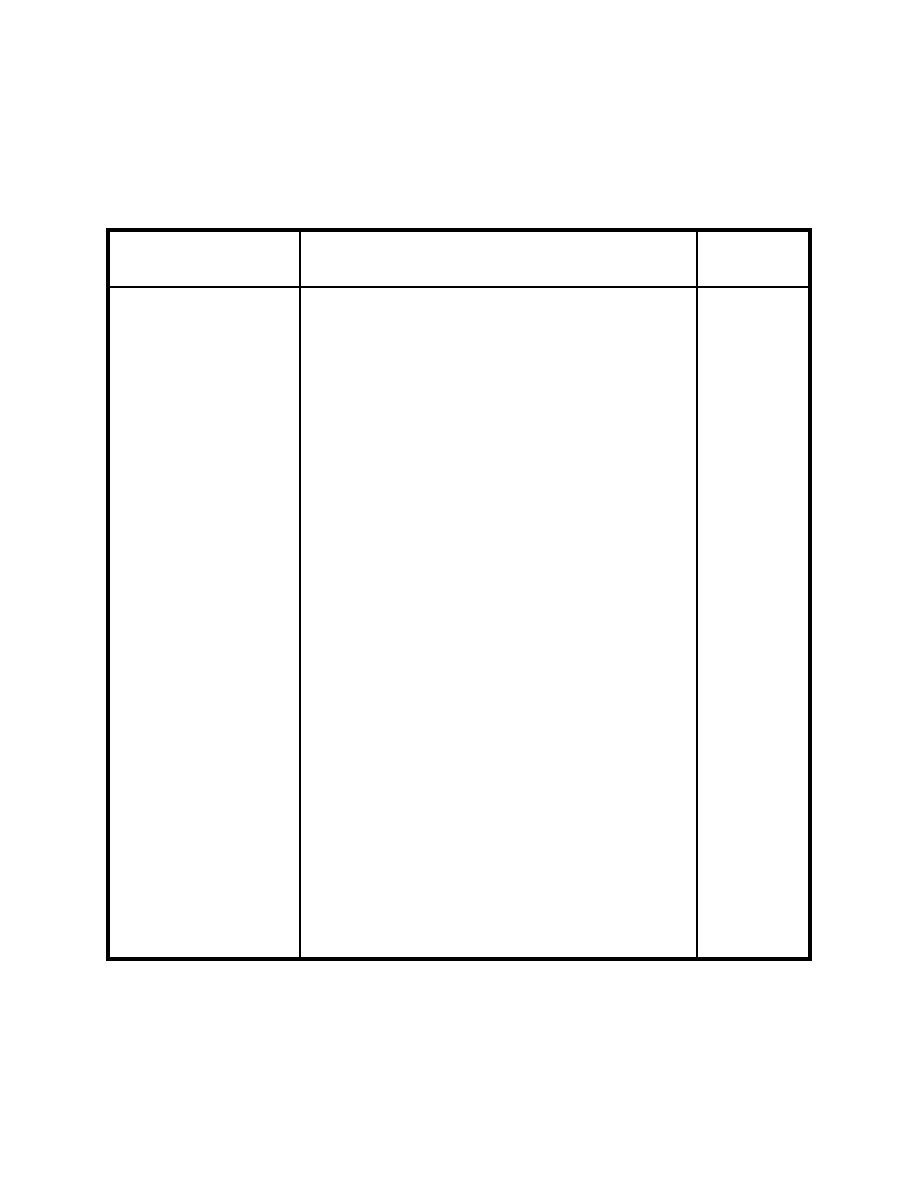

Table 16

Guide for Stuffing Box Inspection

Inspection/

Procedure

Action

(1),(2)

Inspect stuffing box

Ensure that stuffing box glands are moving

SA

freely and that gland bolts and nuts are oiled.

Check for excessive leakage that cannot be

reduced by gland adjustment; if found, proceed

according to the steps below:

Remove old

a) Remove old packing and clean box. If the

V

packing

box has a seal cage, make sure it is located

opposite the sealing liquid inlet.

b) Use packing recommended by manufacturer.

c) Measure the depth of box and sealing liquid

inlet tap. Place enough rings of packing in the

bottom of the box that seal cage is in proper

position once packing is compressed. Do not

try to pack a pump by renewing only the last

three or four rings.

Check packing ring

a) Make sure the packing ring joints are

V

joints

staggered.

Add new packing

a) Cut the packing so that the joints are square

V

after the packing is bent around the shaft.

Packing should be cut about 1/16 inch longer

than measured to be sure that the outside

diameter of the ring hugs the stuffing box wall

rather than the sleeve. Use care in cutting the

rings.

b) Except as detailed below, use the follower

gland and a few convenient equal-length

spacers to compress each ring firmly into place

before inserting the next ring.

92

Previous Page

Previous Page