o Thus the effective area of material reinforcement is

Ar = 2.4 x 1.925 = 4.62 in2

which is more than adequate.

o The designer must also check to see that his

design conforms to the boundary limits along

the surface of the shell as prescribed by the

provisions of Paragraph AD-540.2(a), (b), and

(c).

Of particular importance is AD-540.1 (c)

quoted in Paragraph 6.b.(6) above:

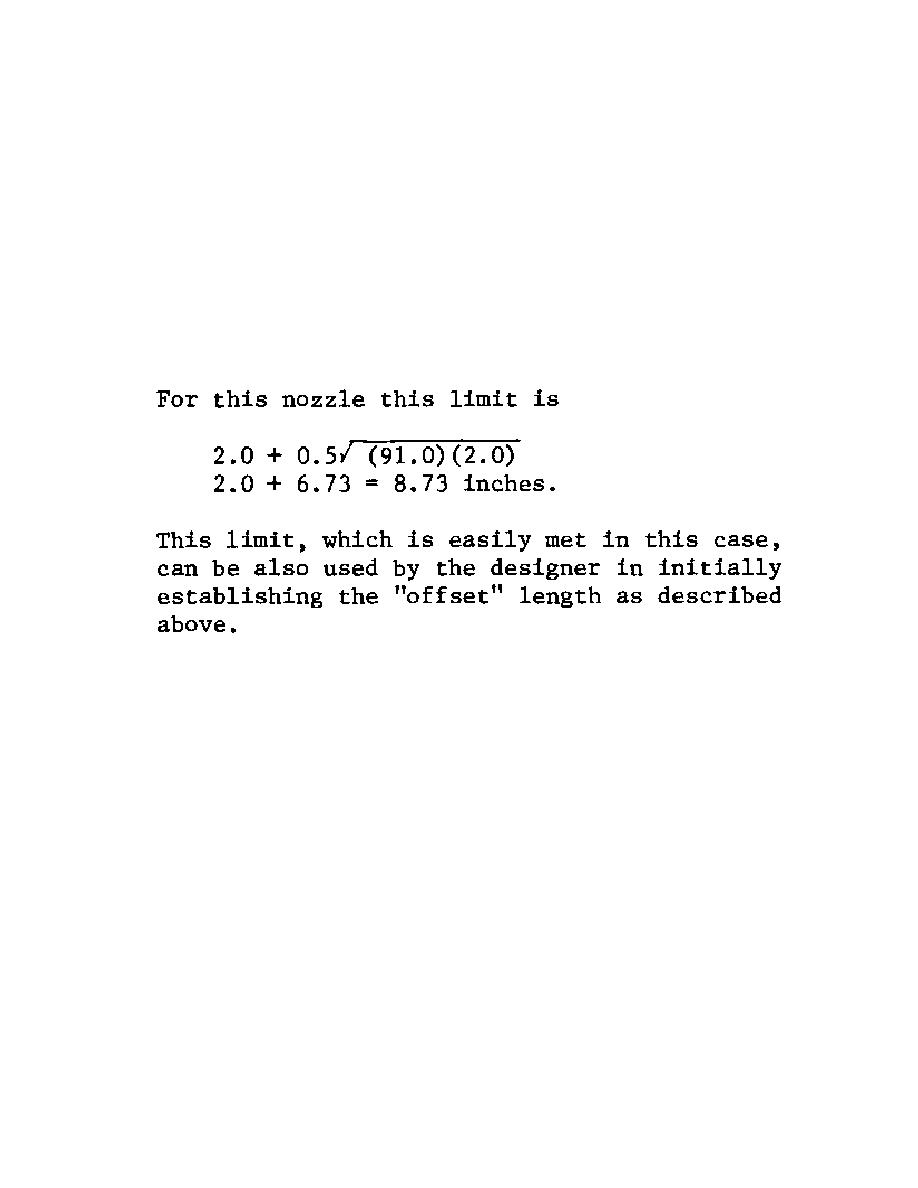

For this nozzle this limit is

o The inner corner radius, r1, is established by

Paragraph 4-613(d) as between 10 percent and

100 percent of the shell thickness. In this case,

r1 was set to 0.5 inches which is 25 percent of

the shell thickness.

o The transition radius r3 is established by

Paragraph 4-613(f)(2) as 2(sin [theta])3 times the

offset. For this configuration nozzle,

[theta] = 90.0 degrees and the offset is 2.4 inches.

Thus r3 = 4.8 inches.

o The final 4.0 inch nozzle configuration is

shown here in Figure 2-10. The choice of an

39-47

Previous Page

Previous Page