UFC 3-570-06

JANUARY 31 2003

conclusive. The preferred method to determine if a dielectric may be shorted is by

potential testing. This method will normally provide an immediate indication if the

dielectric is not shorted, and at the same time provide valuable potential data. If this

method indicates the dielectric may be shorted, other methods of verification are be

required. The radio frequency tester (insulated flange tester) should be used when a

shorted condition is indicated by potential measurements. Alternate methods of

verification may be used to test installed dielectrics. These methods include the pipe

locator method (paragraph 7-7.3), which can determine that an installed dielectric is

bad, but does not give conclusive evidence if the test indicates that the dielectric is

good; and the power supply method (paragraph 7-7.4), which can determine that an

installed dielectric is good, but does not give conclusive evidence if the test indicates

that an installed dielectric is bad.

the dielectric is good, current will flow through the meter and damage could result. If

that current does not damage the meter, the measurement would not indicate a

resistance value. The voltage would be interpreted by the meter as coming from the

internal battery instead of the external electrical circuit being measured.

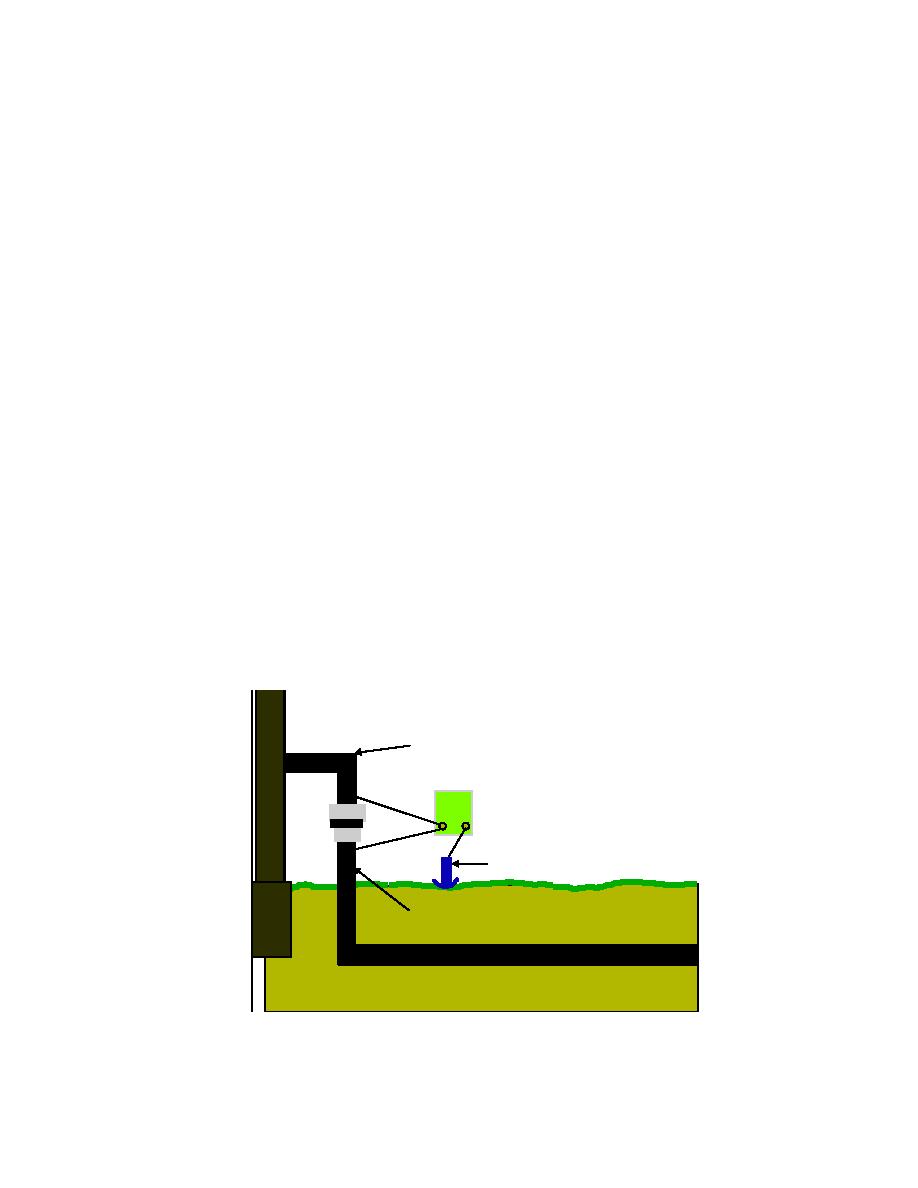

7-7.1

Testing for a Shorted Dielectric. Take a potential measurement of both

sides of the installed dielectric by changing only the structure connection, without

moving the copper/copper sulfate reference electrode.

Figure 7-13. Testing for a Shorted Dielectric

Test Station or

Metallic Contact

to Pipeline

House Side of Dielectric

1

+ -

2

Reference

Electrode

Street Side of Dielectric

7-7.1.1

If the two potential measurements are significantly different (over 10 mV), the

7-23

Previous Page

Previous Page