MIL-HDBK-1164

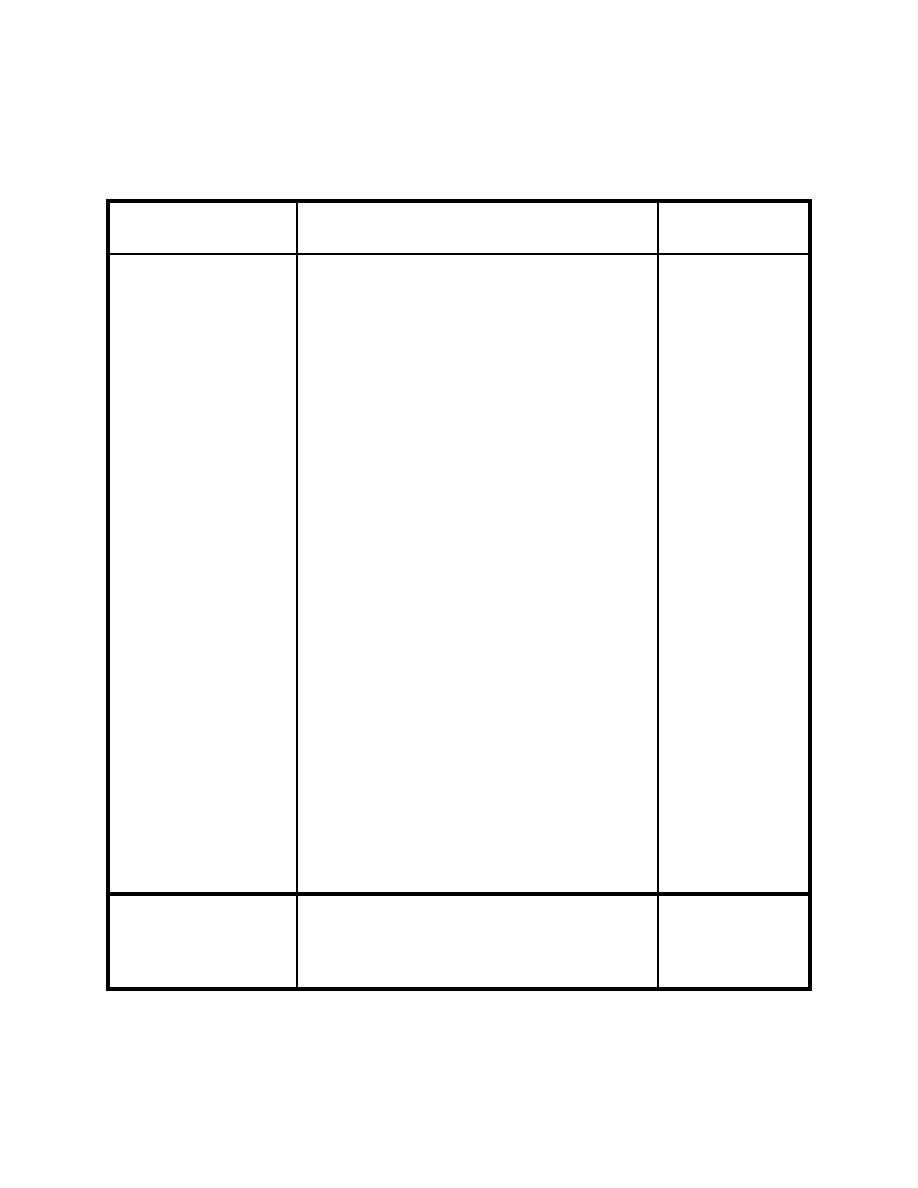

Table 25 (Continued)

Frequency (1),

Inspection

Action

(2)

Plug valves

Lubricate with lubricant stick.

M or Q

Operate all valves; check for corrosion and

Q

foreign matter between plug and seat;

lubricate gearing.

Inspect; dismantle if necessary; clean, wire

A

brush, re-machine plug and body or

replace if condition is beyond re-

machining.

Curb stops

Remove and replace whenever necessary.

V

Multiport valves

Lubricate with grease.

SA

Globe valves

Operate valve to prevent sticking; check

Q

for leakage, adjust packing nut, and

replace packing if necessary.

SA

Check valve closure for tight shutoff; if

valve does not hold, remove valve stem

and disk and regrind seat and disk.

Q

Diaphragm valves

Operate valve; check valve stem and

lubricate as necessary; check for tight

closing.

Check diaphragm for cracks; renew as

A

necessary.

Sluice gates

Operate inactive gates; lubricate stem

M

screws and gears.

Clean valve with wire brush and paint with

A

corrosion-protective paint.

Check seating wedges on valves seating

A

against pressure.

Backflow preventers

Test tightness of unit.

M

Reduced pressure

Power-operated

valves

136

Previous Page

Previous Page