MIL-HDBK-1164

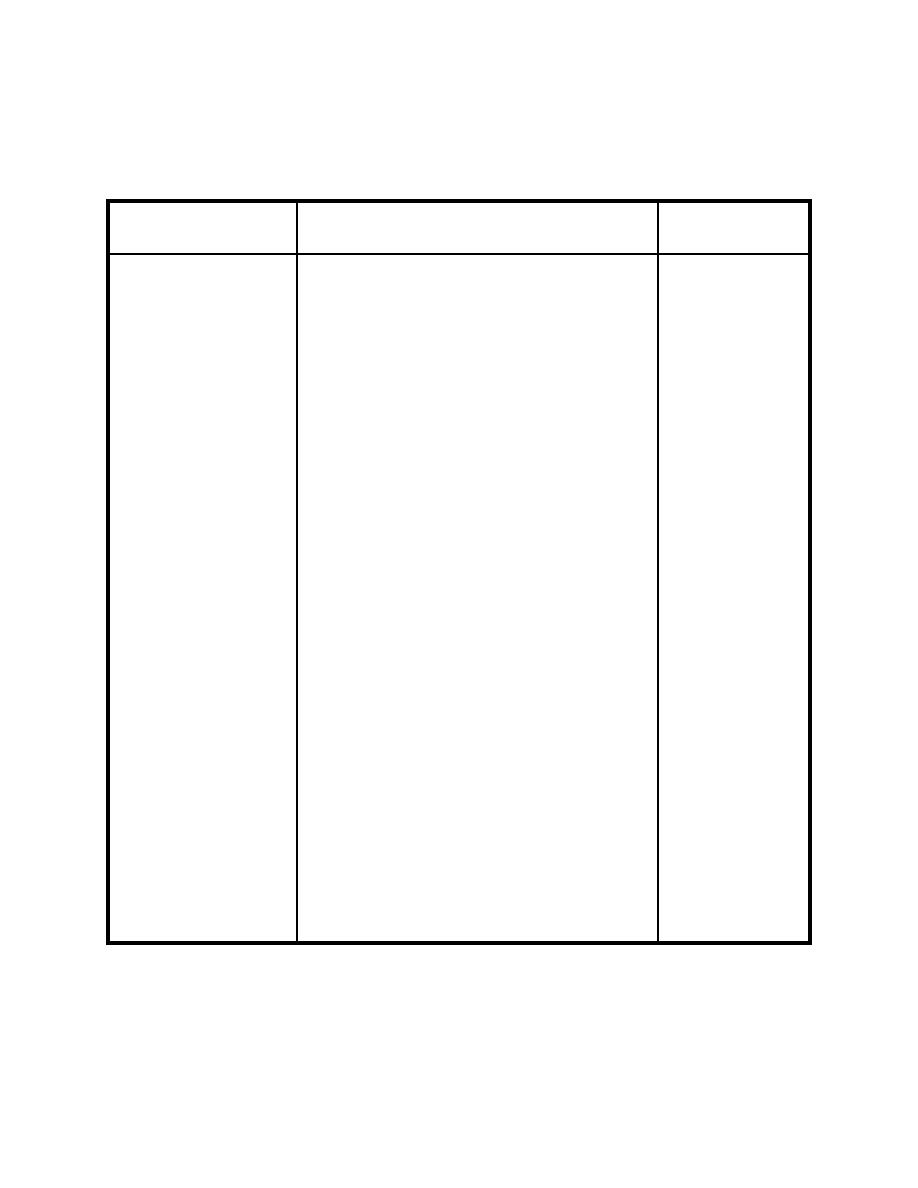

Table 25 (Continued)

Frequency (1),

Inspection

Action

(2)

Valve operator pilot Check control through one full cycle of

M

controls

operation.

Lubricate pins, linkage, packing glands,

M

and adjustment rod threads as necessary;

remove corrosion products; check for

leakage and repair.

Disassemble; inspect unit and clean

A

strainers; examine diaphragm for failure;

regrind or replace worn valve seats.

Automatic valves

A

Air-release valves,

Remove valve from service; inspect float

valve unit.

for leaks, and pins and linkage for

corrosion; remove corrosion products;

clean orifices.

Vault

Inspect for condition of masonry, steps,

A

and manhole covers; repair as necessary.

Altitude valves

Inspect and lubricate.

M

Pilot controls

A

Valve unit and

Disassemble; inspect hydraulic cylinder

operator

and repair; inspect valve, repair, and paint,

as necessary.

A

Check valves

Inspect the closure control mechanism (if

any); clean and adjust as necessary;

check pin wear if balanced disk type;

check seating on ball type.

Disassemble; clean, reseat, and repair as

V

necessary.

Float valves

Inspect float; repair as necessary.

M

Inspect valve and valve operating

A

mechanism.

138

Previous Page

Previous Page