UFC 4-023-03

25 January 2005

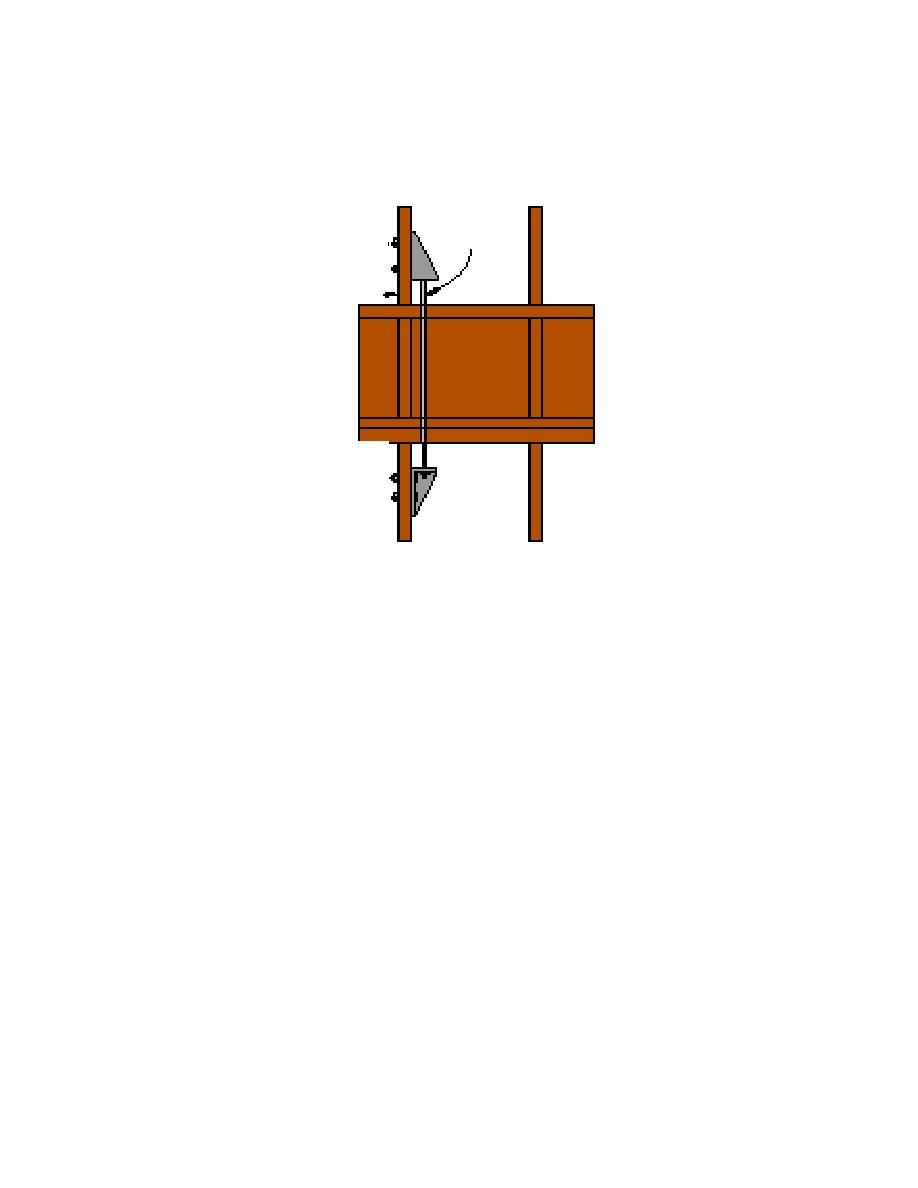

Figure F-6 Holdown Installation for Vertical Ties (Single Shear Shown)

Threaded

rod

Wall stud

Table F-2 and the schematic details show that wood components can easily

carry the required horizontal tie forces, and connections can be designed to transfer

vertical tie requirements. The number of connections and the connection details for

vertical tie forces can be substantial, however, depending on factored loads. Analysis

using the alternate path method to show bridging in lieu of vertical tie capacity may

provide a more economical solution, as discussed next.

F-3

ALTERNATE PATH METHOD FOR WOOD FRAME CONSTRUCTION.

Research on platform wood frame construction has shown potential

mechanisms for bridging over removed members. One mechanism is sheathed walls

acting as deep beams. Consideration should also be given to using a system of rim

beans continuous around the building perimeter at each floor level and at interior load

bearing walls. These rim beams can be designed to support the floor and wall above as

part of the progressive collapse design. Figure F-7 illustrates the use of rim beams.

Figure F-8 illustrates the bridging mechanism enabled through the use of rim beams. In

addition, consideration should be given to building the floor such that the floor is

supported on all sides, even though it is designed to span in one direction. Testing by

TRADA and BRE in the UK demonstrated that the floor has additional strength through

the transverse capacity of the floor that is supported on the walls parallel to the span.

This is illustrated in Figure F-9.

F-8

Previous Page

Previous Page