166

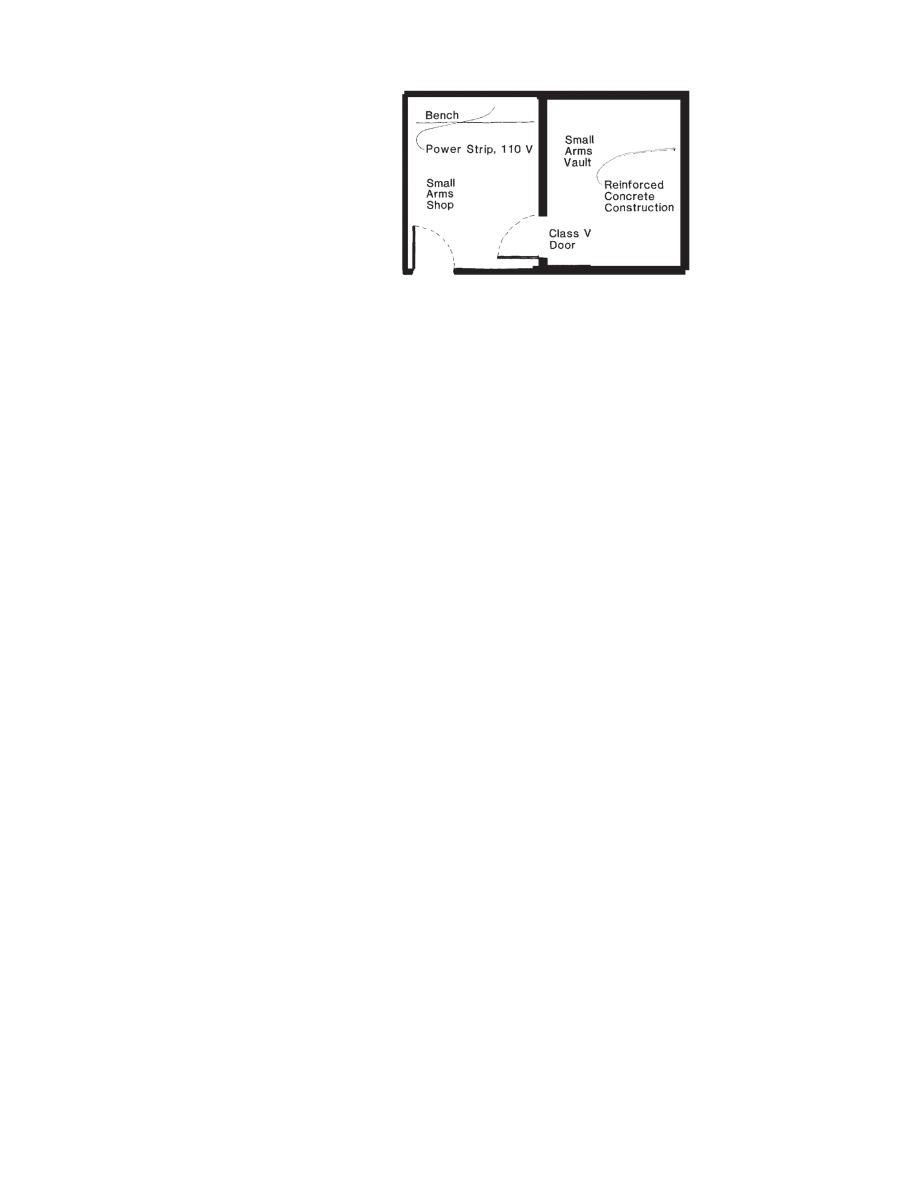

Figure 4-42 Small Arms Repair Room with Arms Vault

4.5.2.2 The typical crane is a 6.8 metric ton (7.5 ton), single-girder,

top-running crane, equipped with a low-headroom, bottom-running

trolley with a wire rope hoist. Structural columns with a supporting

haunch must be strategically placed to support the crane girder and

rail, which supports the bridge crane. The maximum span of the

bridge crane itself will be 18,000 mm (60 ft). It is not economically

feasible to span the entire 24,000 mm (80 ft) width of the building.

Verify clear hook height required with the Tenants, based on the

equipment they service. Some units servicing heavier equipment may

require a crane with a larger lifting capacity.

4.5.2.3 The crane will be Class C, moderate service CMAA Duty

Classification. Provide push button pendant festoon. Minimum and

maximum speeds: hoist .076 m/s (15 fpm) and .127 m/s (25 fpm);

trolley .229 m/s (45 fpm) and .381 m/s (75 fpm); and bridge .382

m/s (75 fpm) and .762 m/s (150 fpm). Provide warning horn and

light when crane is in motion, and warning alarm and light when

crane malfunctions or is overloaded.

4.5.2.4 Space Design Information see OMS workbays, Section

4.3.9 above. See 4.3.9.4 if welding is authorized.

4.5.3 Small Arms Shop and Vault

4.5.3.1 The shop and vault provide space for the repair and storage

of small arms such as rifles, machine guns, grenade launchers, etc.

The shop should be located adjacent to the arms vault with access

to the vault through the shop, similar to the armorer's and arms vault

spaces in a training center.

4.5.3.2 A 110 volt continuous power strip should be provided over

the work benches.

4.5.3.3 Construction of the vault must be in compliance with AR

190-11. See Section 4.2.11 for additional vault design information.

UFC 4-171-05

Previous Page

Previous Page